Material efficiency holds great potential for climate neutrality

by Albert Ludwigs University of Freiburg

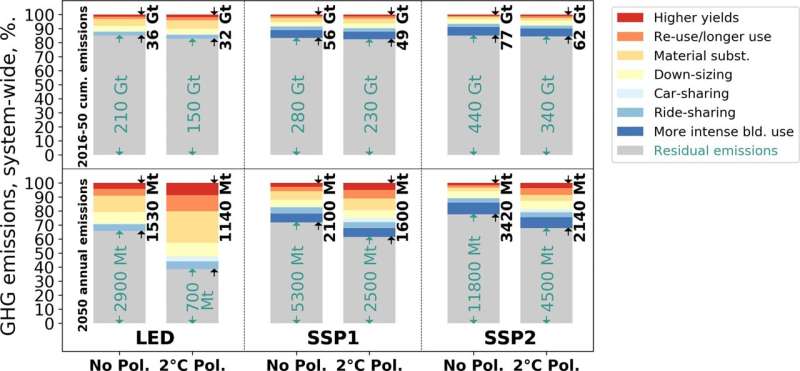

Fig. 1: Total global cumulative (top) and annual 2050 (bottom) greenhouse gas (GHG) emission reductions of the technical potential of ten industrial and demand-side material efficiency (ME) strategies. Results are shown for three socioeconomic (low energy demand (LED) and the shared socioeconomic pathways (SSP1 and SSP2)), and climate policy (No Pol. and 2 °C Pol., see text) scenarios and ME strategy for the passenger-vehicle and residential-building sectors combined. The absolute values in the plot are in megatons (Mt) or gigatons (Gt) of CO2-eq. See the ‘Methods’ section for an overview of the different ME strategies implemented. Credit: DOI: 10.1038/s41467-021-25300-4

More efficient use of materials in residential buildings and cars could save enormous amounts of greenhouse gas emissions by 2050: 20 to 52 gigatons of CO2 equivalents for residential buildings and 13 to 26 gigatons of CO2 equivalents for cars, which amounts to up to two-thirds of current consumption. This is the conclusion reached by a research team led by Dr. Stefan Pauliuk, Assistant Professor of Sustainable Energy and Material Flow Management at the University of Freiburg.

For this purpose, the scientists analyzed 10 global strategies for material efficiency (ME), such as the reuse of scrap from manufacturing, and calculated their joint maximum potential if they were consistently implemented by 2040 and flanked by a strict climate policy. In the case of residential buildings, wood construction and reducing the living space per capita show the greatest savings potential. For passenger vehicles, it's ride-sharing and car-sharing. "This shows that material efficiency can be a key to becoming largely carbon neutral," says Pauliuk. "The potentials are enormous and should be used more." The research team recently presented its findings in the journal Nature Communications.

What if scenarios for various degrees of material efficiency

With a team of international researchers, including Prof. Dr. Edgar Hertwich from the Norwegian University of Science and Technology/Norway, Pauliuk looked at the life cycles of materials for housing and car construction and calculated how many greenhouse gas emissions could be saved by 2050 through a broad and ambitious introduction of material efficiency (ME) measures in combination with a strict climate policy. The calculation considers ten ME strategies. These include supply-side measures, such as reusing scrap from manufacturing; demand-side measures, such as reusing products; and more efficient use of products through car sharing and shared housing.

Alongside this, the scientists determined the future changes in material flows and energy consumption due to higher material yields, lighter design, material substitution, longer service life, higher service efficiency, reuse and recycling. In doing so, the computational model captures the production, demand, use and recycling of six climate-relevant materials: aluminum, cement, copper, plastics, steel and wood. "The analysis generates a range of what-if scenarios for various degrees of material efficiency in the vehicle and building sectors and associated key material cycles against different socioeconomic and climate policy backgrounds," Pauliuk explains.

Material efficiency must be given higher priority in climate policy

According to the researchers, their study shows that renewable energy alone is not enough to achieve deep emission reductions in the residential sector, but that additional efficiency measures are needed. The same applies to passenger cars, where electrification and conversion to low-carbon electricity must go hand in hand, they say.

Pauliuk concludes that "if material efficiency strategies are given a similarly high priority as energy efficiency measures, achieving the Paris goal of limiting global warming to well below 2 degrees Celsius will be easier. Measures to improve material efficiency can be easily implemented, so they should be given higher priority in climate policy."

Explore further Using materials efficiently can substantially cut greenhouse gas emissions

More efficient use of materials in residential buildings and cars could save enormous amounts of greenhouse gas emissions by 2050: 20 to 52 gigatons of CO2 equivalents for residential buildings and 13 to 26 gigatons of CO2 equivalents for cars, which amounts to up to two-thirds of current consumption. This is the conclusion reached by a research team led by Dr. Stefan Pauliuk, Assistant Professor of Sustainable Energy and Material Flow Management at the University of Freiburg.

For this purpose, the scientists analyzed 10 global strategies for material efficiency (ME), such as the reuse of scrap from manufacturing, and calculated their joint maximum potential if they were consistently implemented by 2040 and flanked by a strict climate policy. In the case of residential buildings, wood construction and reducing the living space per capita show the greatest savings potential. For passenger vehicles, it's ride-sharing and car-sharing. "This shows that material efficiency can be a key to becoming largely carbon neutral," says Pauliuk. "The potentials are enormous and should be used more." The research team recently presented its findings in the journal Nature Communications.

What if scenarios for various degrees of material efficiency

With a team of international researchers, including Prof. Dr. Edgar Hertwich from the Norwegian University of Science and Technology/Norway, Pauliuk looked at the life cycles of materials for housing and car construction and calculated how many greenhouse gas emissions could be saved by 2050 through a broad and ambitious introduction of material efficiency (ME) measures in combination with a strict climate policy. The calculation considers ten ME strategies. These include supply-side measures, such as reusing scrap from manufacturing; demand-side measures, such as reusing products; and more efficient use of products through car sharing and shared housing.

Alongside this, the scientists determined the future changes in material flows and energy consumption due to higher material yields, lighter design, material substitution, longer service life, higher service efficiency, reuse and recycling. In doing so, the computational model captures the production, demand, use and recycling of six climate-relevant materials: aluminum, cement, copper, plastics, steel and wood. "The analysis generates a range of what-if scenarios for various degrees of material efficiency in the vehicle and building sectors and associated key material cycles against different socioeconomic and climate policy backgrounds," Pauliuk explains.

Material efficiency must be given higher priority in climate policy

According to the researchers, their study shows that renewable energy alone is not enough to achieve deep emission reductions in the residential sector, but that additional efficiency measures are needed. The same applies to passenger cars, where electrification and conversion to low-carbon electricity must go hand in hand, they say.

Pauliuk concludes that "if material efficiency strategies are given a similarly high priority as energy efficiency measures, achieving the Paris goal of limiting global warming to well below 2 degrees Celsius will be easier. Measures to improve material efficiency can be easily implemented, so they should be given higher priority in climate policy."

Explore further Using materials efficiently can substantially cut greenhouse gas emissions

More information: Stefan Pauliuk et al, Global scenarios of resource and emission savings from material efficiency in residential buildings and cars, Nature Communications (2021). DOI: 10.1038/s41467-021-25300-4

Journal information: Nature Communications

Provided by Albert Ludwigs University of Freiburg

No comments:

Post a Comment