FEBRUARY 26, 2024

Gaseous hydrogen is the default for fuel-cell vehicles, but Daimler Truck is experimenting with liquid hydrogen for large commercial vehicles—and it's a technology that has the potential to cross over to passenger vehicles, eventually.

The truck maker has partnered with Linde Engineering to set up a public liquid hydrogen station in Wörth am Rhein, Germany. Called sLH2, it will fuel Mercedes-Benz GenH2 trucks from five companies taking part in a customer trial starting later this year, according to a Daimler press release.

The station uses a new type of pump that raises the pressure of liquid hydrogen, turning it into supercooled liquid hydrogen, according to Daimler. This allows for higher storage density, a smaller footprint for the station, and lower energy consumption, the company claims.

Daimler sLH2 liquid hydrogen fueling station

Refueling speed is also claimed to be comparable to diesel trucks. Pumps can add 621 miles of range in 10 to 15 minutes, Daimler claims, while enough liquid hydrogen can be stored onsite for 10 hours of non-stop refueling, with additional capacity easily added by refilling the tanks.

The downside is that, to maintain a liquid rather than a gaseous state, hydrogen must be cooled to -423 degrees Fahrenheit. The installation also requires special materials. So the cost of implementing such a solution may be prohibitive.

This isn't the first we've heard of long-haul liquid-hydrogen semis from Daimler. The company has been discussing liquid hydrogen since showing a concept semi truck in 2020. That truck had the same GenH2 badging as the ones to be used in the upcoming customer trial, but with more futuristic styling.

Daimler sLH2 liquid hydrogen fueling station

Liquid hydrogen tech is also something that Airbus has been working on for jet engines—as an alternative to fuel cells and electric turboprops. Although storage issues remain complex there, too, some see it as a replacement for jet fuel.

Meanwhile Nikola is pushing ahead with its Hyla refueling network, which is designed around gaseous hydrogen, as part of a strategic plan to establish up to 60 hydrogen refueling solutions in the coming years.

Gaseous hydrogen is the default for fuel-cell vehicles, but Daimler Truck is experimenting with liquid hydrogen for large commercial vehicles—and it's a technology that has the potential to cross over to passenger vehicles, eventually.

The truck maker has partnered with Linde Engineering to set up a public liquid hydrogen station in Wörth am Rhein, Germany. Called sLH2, it will fuel Mercedes-Benz GenH2 trucks from five companies taking part in a customer trial starting later this year, according to a Daimler press release.

The station uses a new type of pump that raises the pressure of liquid hydrogen, turning it into supercooled liquid hydrogen, according to Daimler. This allows for higher storage density, a smaller footprint for the station, and lower energy consumption, the company claims.

Daimler sLH2 liquid hydrogen fueling station

Refueling speed is also claimed to be comparable to diesel trucks. Pumps can add 621 miles of range in 10 to 15 minutes, Daimler claims, while enough liquid hydrogen can be stored onsite for 10 hours of non-stop refueling, with additional capacity easily added by refilling the tanks.

The downside is that, to maintain a liquid rather than a gaseous state, hydrogen must be cooled to -423 degrees Fahrenheit. The installation also requires special materials. So the cost of implementing such a solution may be prohibitive.

This isn't the first we've heard of long-haul liquid-hydrogen semis from Daimler. The company has been discussing liquid hydrogen since showing a concept semi truck in 2020. That truck had the same GenH2 badging as the ones to be used in the upcoming customer trial, but with more futuristic styling.

Daimler sLH2 liquid hydrogen fueling station

Liquid hydrogen tech is also something that Airbus has been working on for jet engines—as an alternative to fuel cells and electric turboprops. Although storage issues remain complex there, too, some see it as a replacement for jet fuel.

Meanwhile Nikola is pushing ahead with its Hyla refueling network, which is designed around gaseous hydrogen, as part of a strategic plan to establish up to 60 hydrogen refueling solutions in the coming years.

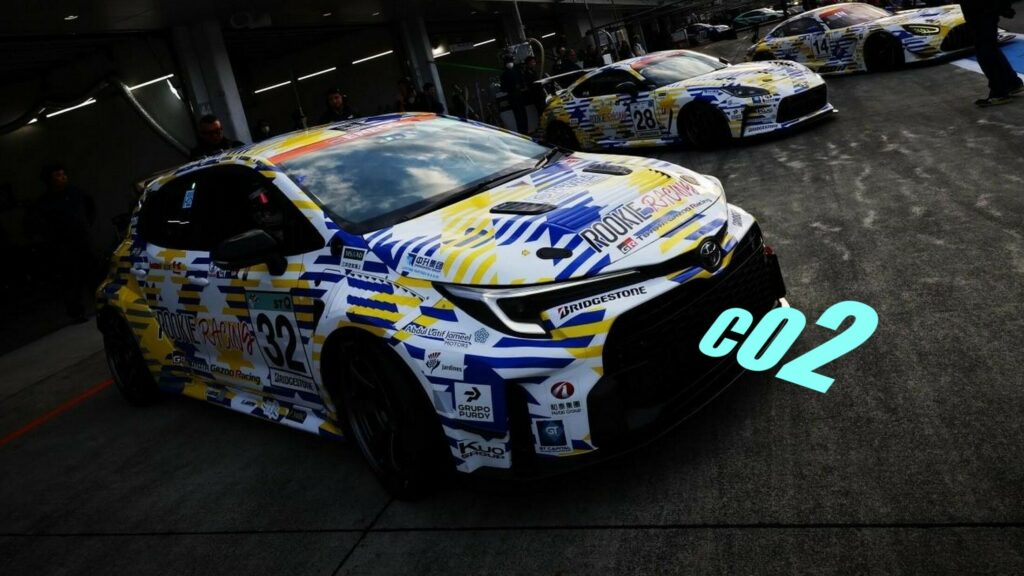

Toyota Tests Tech That Sucks CO2 From The Air On GR Corolla

A filter could suck up CO2 in the air as cars drive, but right now the technology is slow and inconvenient

by Sebastien Bell

February 26, 2024

While Toyota has been cautious about fully transitioning to an all-electric lineup, a stance supported by some analysts, the company is actively pursuing alternative green technologies. One concept in development not only aims to enhance the eco-friendliness of its new vehicles but also tackle the environmental aftermath of outdated internal combustion engines.

Toyota is developing filters that could be integrated into the front of its vehicles to suck carbon dioxide from the atmosphere. The company is currently experimenting with this concept on its hydrogen combustion GR Corolla racecar. According to Toyota, initial tests suggest that this innovation could potentially render its cars carbon negative rather than merely carbon neutral.

The technology is clever in that it doesn’t require any additional power to work. Circular filters at the front of the car capture carbon dioxide, then waste heat from the engine is used to dissolve it into a liquid that can be disposed of. That means that this technology could also work in regular combustion engines, not just those who run on hydrogen.

Read: Toyota Turns Garbage Into Electricity, Makes Battery Recycling Cleaner Too

In Toyota’s vision, that would create a vehicle that actually cleans the air as it is being driven. Unfortunately, the technology is still a long way off. In its test, the filters only captured 20 grams of carbon dioxide in 20 laps of running (57 miles/91 km). That’s better than nothing, but engines running on fossil fuels emit 8,887 grams of carbon dioxide per gallon they consume, on average.

Bigger filters could suck up more carbon dioxide, but they would likely be difficult to package in passenger vehicles. However, deploying them in commercial vehicles, such as Hino trucks, could facilitate the advancement of this technology.

What’s more problematic is that there is still debate about how to safely deal with the liquid that contains the CO2. Furthermore, the technology is currently pretty inconvenient. In the GR Corolla Toyota used to test it, the filters needed to be changed manually during every pit stop, leading to questions about waste, among other things.

Yet, if Toyota can successfully develop the technology to passively suck CO2 from the air while drivers operate their vehicles, it could become a highly valuable innovation. However, its development comes as the company is attempting to rehabilitate its green image, following reports that it contributed to the campaigns of climate change denying politicians in the U.S.

Bigger filters could suck up more carbon dioxide, but they would likely be difficult to package in passenger vehicles. However, deploying them in commercial vehicles, such as Hino trucks, could facilitate the advancement of this technology.

What’s more problematic is that there is still debate about how to safely deal with the liquid that contains the CO2. Furthermore, the technology is currently pretty inconvenient. In the GR Corolla Toyota used to test it, the filters needed to be changed manually during every pit stop, leading to questions about waste, among other things.

Yet, if Toyota can successfully develop the technology to passively suck CO2 from the air while drivers operate their vehicles, it could become a highly valuable innovation. However, its development comes as the company is attempting to rehabilitate its green image, following reports that it contributed to the campaigns of climate change denying politicians in the U.S.

No comments:

Post a Comment