GREAT LAKES

Not NAABSA-Ready: Laker's Load Plan Caused Grounding and Hull Damage

The National Transportation Safety Board has released its report on the double grounding of the laker John J. Boland in April 2023, and it found that a faulty load plan and inadequate SMS guidance on underkeel clearance set the conditions for a casualty.

On April 21, 2023, the self-unloading laker John J. Boland was alongside the Carmeuse Americas dock at Port Dolomite, Michigan, moored with her port side to the pier. The controlling depth at the pier was 23 feet, and the offgoing first mate's load plan called for maintaining a draft of 26 feet 8 inches or less, based on NOAA water level gage data.

At 1517 hours, the shoreside conveyor on the pier began loading the Boland's holds. The first mate was on deck supervising, and his oncoming relief arrived at about 2000. The new first mate took over supervision of the loading in the early hours of the 22nd.

The work continued until about 0815 in the morning, and then the crew set about trimming the vessel by adding small amounts of cargo to different hatches fore and aft.

The newly-arrived first mate decided to load the forward holds to bring the forward draft to 26 feet 10 inches, knowing that as the crew loaded the after hatches it would raise the bow and balance out the ship fore and aft. However, the bow's draft stopped at 26 feet 7 inches. The first mate immediately knew that the Boland had made contact with the bottom, which he told investigators was a common occurrence during loading (the master agreed that it had happened "numerous" times at the same dock).

To free the ship from the mud, the first mate swung the ship's self-unloading boom outboard, inducing a starboard list. The master also saw that the vessel was "stuck," and he had the crew haul on a forward leading spring line to pull the vessel's bow off the dock. This maneuver worked, and the crew resumed loading the after hatches. At that time, the forward draft settled at 26 feet 10 inches.

As the crew and the conveyor operator loaded the after hatches, the vessel took on a starboard list, away from the pier, and the aft draft stopped increasing when it reached 26 feet 3 inches. The vessel was aground again, and the master called a halt to loading.

This time, efforts to free the ship took longer. Once away from the pier at last, it immediately listed to port.

The master decided not to correct the list, and he initially assumed that it had been caused by uneven loading of the cargo. At 1130 hours, he navigated the vessel out into the channel, and then had the crew transfer ballast until they had eliminated the list.

Since the issues at the dock had prevented an accurate measurement of the vessel's draft marks, the master brought the vessel to a halt at a safe position and ordered the crew to launch the workboat for a draft survey. They checked the draft marks on the port side, sheltered from choppy water, and they recorded the draft as 26 feet 6 inches forward and 27 feet 9 inches aft - over a foot more than planned.

At about 1445, the master ordered the crew to open the number 1 and 2 ballast tanks to inspect for damage. They found about two feet of water in each tank, and more water was entering the number one and two port ballast tanks. They started up the ballast pumps, which had enough capacity to keep up with and reduce the flooding.

The master diverted to a safe anchorage in nearby North Bay, Michigan, arriving and anchoring at 1750 hours.

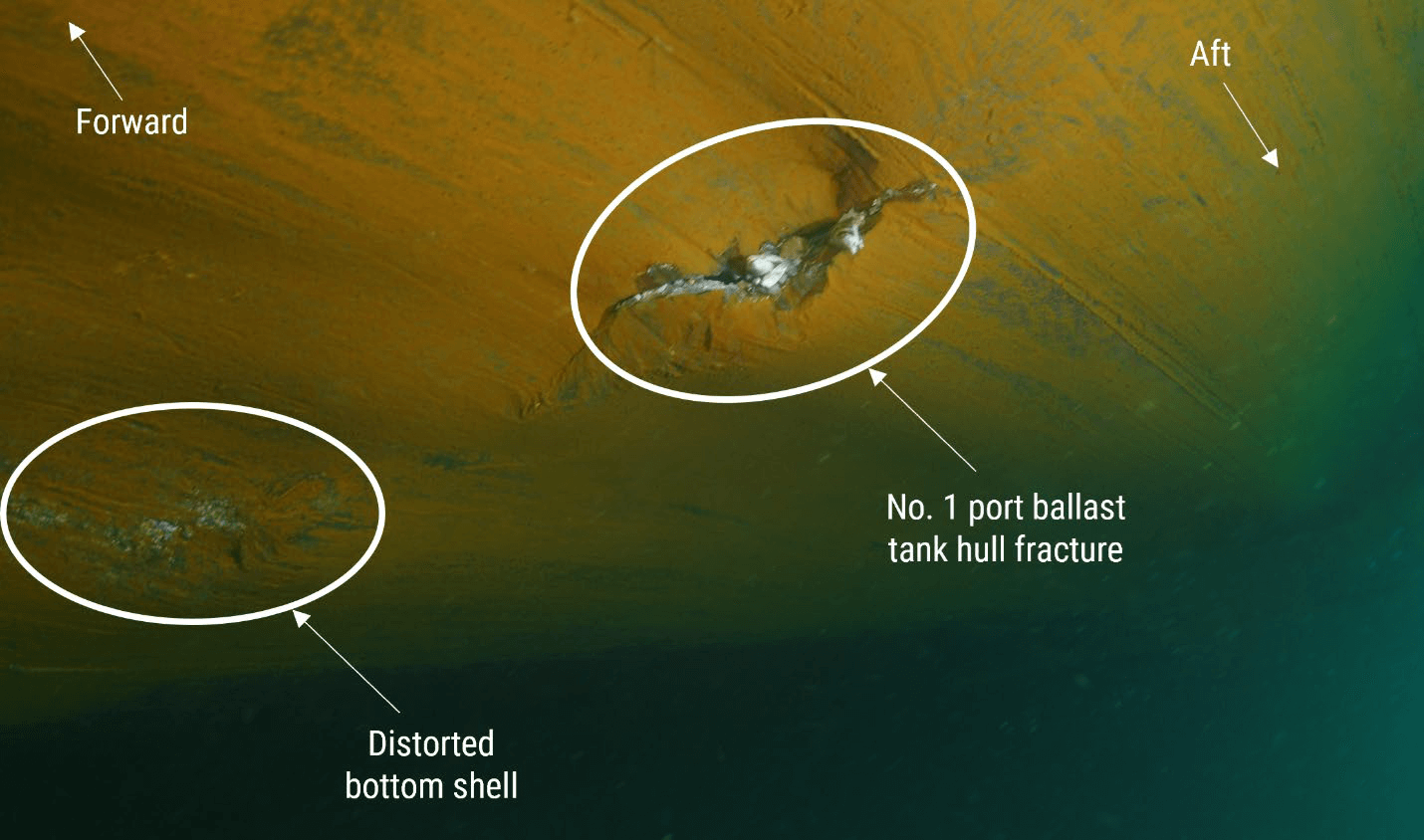

Class arrived to survey the vessel later on the 22nd. The surveyor found four hull fractures on the port side's bottom plating in the number 1 and 2 port ballast tanks. Some framing members in these tanks were distorted as well, and the number 3 and 4 port side ballast tanks showed distortion to hull plating and framing, but no fractures.

Courtesy NTSB

The surveyor and the Coast Guard agreed that the Boland could finish its voyage to its destination and discharge its cargo before transiting to a drydock for repair. The cost of fixing the hull damage came to about $775,000.

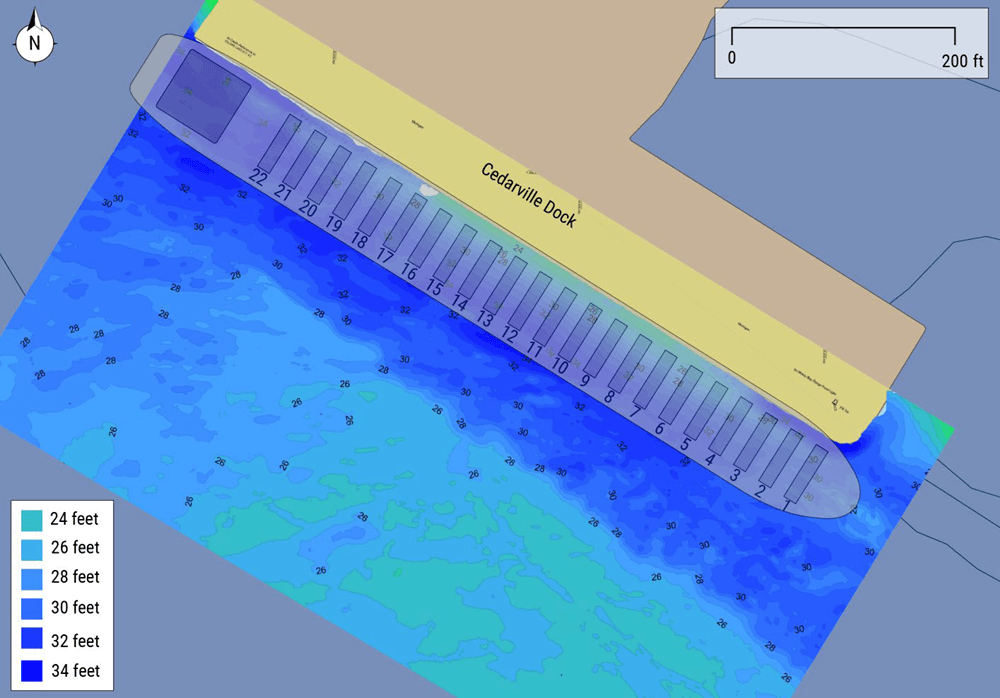

NTSB found that the company's draft guidance for the Cedarville dock called for keeping the vessel 12 feet off the pier during trimming, because of a known shoal directly alongside the wharf. That guidance did not get incorporated into the offgoing first mate's load plan. A post-casualty bathymetric survey found that the shoal just off the dock measured about 24-26 feet in depth, and extended about 15 feet out into the channel.

Courtesy NTSB

NTSB concluded that when the oncoming first mate tried to load the Boland down at the bow, he brought the port side of the bottom into contact with the known shoal alongside the pier. When Boland developed a starboard list because the port side was resting on the shoal, the crew tried to correct it by loading more on the port side, placing further stress on the bottom plating.

"Although the forward draft that it stopped at was still within the limits of the load plan, it exceeded the depth of the shoal by 2 to 3 inches," found NTSB. "Therefore, the load plan for the John J Boland was inadequate because it did not take into account the shoaling at the Cedarville Dock."

NTSB checked the operating company's SMS, and found that it did not specify a safety factor for underkeel clearance for its officers to use in formulating load plans; without guidance, the first mate omitted a UKC safety factor and formulated a load plan that exceeded actual depth alongside. NTSB also concluded that the first mate and master aboard the Boland had become too comfortable with going aground alongside the pier.

"Based on their previous experience on vessels that had contacted bottom during loading operations without incurring damage, the master and first mate likely became desensitized to the risk of vessel damage associated with grounding," NTSB concluded.

Internationally, more than a few inland ports accept grounding as a routine condition of cargo operations, and some self-declare that they operate as "not always afloat but safely aground" (NAABSA) terminals. In some regions, this is so common that the charterparty will lay out the division of liability if the ship is damaged during a planned NAABSA grounding; this is a common source of disputes, according to leading insurer Gard. For routine operations in NAABSA ports, some operators purchase purpose-built vessels designed to rest on the bottom during cargo operations.

No comments:

Post a Comment