Steel making could get a makeover

University of Minnesota

image:

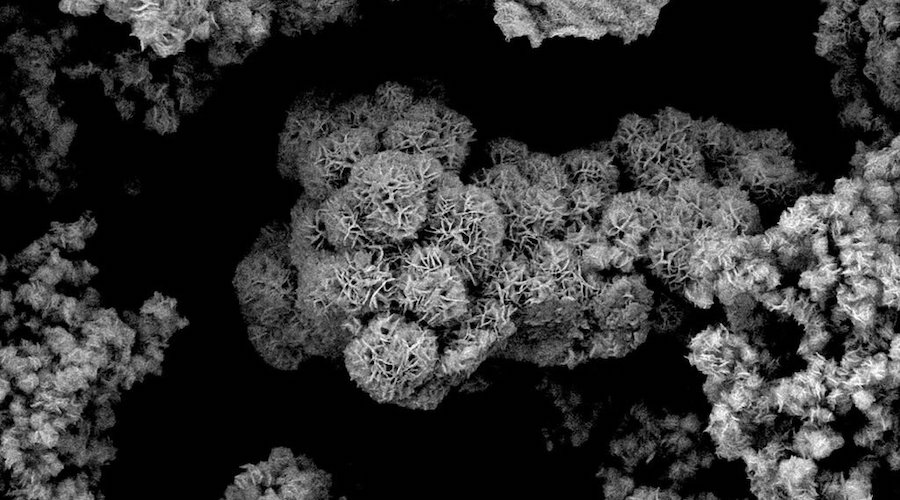

Ph.D. student, Jae Hyun Nam, worked in the University of Minnesota Characterization Facility to complete these nanometer scale observations.

view moreCredit: Kalie Pluchel, University of Minnesota

Researchers investigate clean and efficient new method for iron production

MINNEAPOLIS / ST. PAUL (09/29/2025) — A research team at the University of Minnesota Twin Cities has investigated a new method to produce iron, the main component of steel. For the first time, the researchers were able to observe chemical reactions and iron formation in real-time at the nanometer scale.

This breakthrough has the potential to transform the global iron and steel production industry by improving energy efficiency and lowering costs. The study was recently published in Nature Communications, a peer-reviewed, high impact scientific journal.

According to the paper, the iron and steel industry is the largest industrial emitter of carbon dioxide, responsible for approximately 7 percent of the total global carbon dioxide emissions. Traditional methods for producing iron are pollution-heavy, relying on coke–a type of coal–to remove oxygen from iron ore—a process that has remained largely unchanged for centuries.

This method eliminates the CO2 emissions that have traditionally come from iron-making that can be performed at room temperature. This makes it potentially more efficient and desirable to industry and opens new pathways to innovation in the U.S. based manufacturing industry.

The new process uses hydrogen gas plasma, an ionized gas which dissociates the hydrogen gas producing an abundance of highly reactive hydrogen atoms. When the iron is exposed to this plasma, the highly reactive hydrogen atoms strip the oxygen from the ore producing pure iron and water vapor.

“We developed a new technique that allows us to monitor plasma-material interactions at the nanometer scale, which has never been done before,” said Jae Hyun Nam, first author on the paper and a Ph.D. student in the University of Minnesota Department of Mechanical Engineering.

The team partnered with Hummingbird Scientific, a company that builds products for electron, X-ray and ion microscopy, to create a specialized holder that fits inside of an transmission electron microscope.

"Overcoming the technical challenges of this research was one of the most difficult experiments we've done," said Peter Bruggeman, a senior author on the paper and University of Minnesota Distinguished McKnight University Professor in the Department of Mechanical Engineering. “Generating plasmas on a scale around the size of a human hair, which is required to obtain the nanometer resolution, creates significant engineering challenges which we collaboratively tackled with Hummingbird Scientific.”

Previous optical methods could only be viewed at a few hundred nanometers—about a thousand times smaller than the diameter of a human hair. This new method will allow researchers to see things at a nanometer resolution, which is 100 times better than previous research.

“Creating plasma could be energetically a lot more efficient than heating the material," said Andre Mkhoyan, a senior author on the paper and professor and Ray D. and Mary T. Johnson Chair in the University of Minnesota Department of Chemical Engineering and Materials Science. “This innovation could lead to materials being modified with lower energy consumption, ultimately making processes more economically efficient.”

Read the full paper entitled, “Revealing the mechanisms of non-thermal plasma-enabled iron oxide reduction through nanoscale operando TEM” on the Nature Communications website.

Journal

Nature Communications

Article Title

Revealing the mechanisms of non-thermal plasma-enabled iron oxide reduction through nanoscale operando TEM