The Nuclear Waste Problem Haunting UK Energy Expansion

- Effective nuclear waste management is a critical global challenge, particularly for countries like the UK looking to expand their nuclear power sectors.

- The UK has a substantial amount of existing radioactive waste and is struggling to implement a long-term disposal solution, with the proposed underground geological disposal facility facing significant hurdles and cost concerns.

- Public and local community pushback against potential nuclear waste sites further complicates the development of new disposal facilities, making finding a solution an ongoing and difficult process.

One of the biggest hurdles to expanding the global nuclear power sector is the concern over how best to manage nuclear waste. While some believe they have found sustainable solutions to dispose of nuclear waste, there is still widespread debate around how safe these methods are and the potential long-term impact of waste disposal and storage. In the United Kingdom, the government has put nuclear power back on the agenda, after decades with no new nuclear developments; however, managing nuclear waste continues to be a major barrier to development.

Nuclear waste remains radioactive for around 10,000 years, meaning it is vital that governments dispose of all waste effectively to ensure people and the environment are kept safe in the long term. As more governments welcome a new nuclear era, they must address nuclear waste concerns and establish clear guidelines and regulations on disposal to ensure that all nuclear power companies adhere to strong safety standards and practices.

There are three types of nuclear waste: low-, intermediate-, and high-level radioactive waste. Most of the waste produced at nuclear facilities is lightly contaminated, including items such as tools and work clothing, with a level of around 1 percent radioactivity. Meanwhile, spent fuel is an example of high-level waste, which contributes around 3 percent of the total volume of waste from nuclear energy production. However, this contains around 95 percent of the radioactivity, making adequate waste management of these products extremely important.

In the U.K., the government continues to battle with how best to dispose of its nuclear waste, as it looks to expand the industry over the coming decades. The U.K. has 700,000 cubic metres of radioactive waste from its previous nuclear power activities, a figure that will grow as more nuclear projects come online. The government is now considering the development of a massive underground nuclear dump, known as a geological deposit facility (GDF), to safely dispose of the waste. While no site has been confirmed for development, it is expected to be developed in one of two potential sites in Cumbria, in the north of England.

A U.K. Department for Energy Security and Net Zero spokesperson stated, “Constructing the UK’s first geological disposal facility will provide an internationally recognised safe and permanent disposal of the most hazardous radioactive waste.” They added, “Progress continues to be made in areas taking part in the siting process for this multibillion-pound facility, which would bring thousands of skilled jobs and economic growth to the local area.”

However, the U.K. Treasury believes the government’s plan for the waste dump is “unachievable”, rating the project as “red”, or not possible, in a recent assessment. This means that, “There are major issues with project definition, schedule, budget, quality and/or benefits delivery, which at this stage do not appear to be manageable or resolvable. The project may need rescoping and/or its overall viability reassessed.” In addition, there are concerns over the projected project cost, which is expected to be anywhere up to $73 billion.

Richard Outram, the secretary of Nuclear Free Local Authorities, explained, “The Nista red rating is hardly surprising. The GDF process is fraught with uncertainties, and the GDF ‘solution’ remains unproven and costly.”

At present, the U.K. stores most of its nuclear waste at its Sellafield facility in Cumbria, which is viewed as one of the most complex and hazardous nuclear sites worldwide. However, with the planned decommissioning of several power plants and the development of new nuclear facilities, the government must address its imminent waste issue. This is a long-term problem, with it expected to take until 2150 to dispose of the country’s existing waste into a GDF, if one is developed, before disposing of new waste.

In June, Lincolnshire County Council withdrew from being a potential site for the GDF after engaging with communities about the proposal. This is a common problem with developing nuclear waste sites, as the pushback in proposed waste regions often prevents development due to a not-in-my-backyard perspective from residents in the area. It is still unclear whether communities in Cumbria will hold a similar opinion. Corhyn Parr, the CEO of Nuclear Waste Services, said, “A GDF requires a suitable site and a willing community and will only be developed when both are in place.”

Several countries around the globe are battling with how best to dispose of old and new nuclear waste, as a nuclear renaissance is starting to be seen, in line with global aims for a green transition. While nuclear power is now viewed as extremely safe and clean, there are pressing concerns around the adequate disposal of waste, which can be extremely harmful to human health and the environment if improperly managed, that must be rapidly addressed.

By Felicity Bradstock for Oilprice.com

Inner containment dome in place at Haiyang 4

_54393.jpg)

The steel containment vessel of the CAP1000 - the Chinese version of the Westinghouse AP1000 - consists of six modules: a bottom head, a cylindrical shell (comprising rings one to four), and a top head. It serves as a crucial barrier to prevent the release of radioactive material and is a key component in implementing passive safety functions.

On 6 September, the top head of the containment vessel for Haiyang 4 - manufactured by CNNC Equipment Corporation - was hoisted and precisely positioned on top of the containment structure. The entire process to install the top head - measuring about 40 metres in diameter, 11 metres in height and weighing 658 tonnes - took 3 hours and 22 minutes.

"With this, the initial shape of the reactor building has been realised, and the nuclear island construction has shifted from civil engineering to installation," State Power Investment Corporation (SPIC) said. A steel and concrete outer dome will next be installed over the inner dome.

(Image: SPIC)

The CAP1000 reactor design uses modular construction techniques, enabling large structural modules to be built at factories and then installed at the site. This means that more construction activities can take place at the same time, reducing the time taken to build a plant as well as offering economic and quality control benefits.

"As the contractor of the steel containment vessel, CNNC Equipment Corporation fully implements the concept of 'factory prefabrication and modular construction', prefabricates relevant sub-modules in the production workshop, and completes the assembly, hoisting and installation of the modules at the nuclear power site, greatly improving the efficiency of project construction," SPIC said.

The construction of two CAP1000 reactors at Haiyang - which is already home to two AP1000 units - was approved by China's State Council in April 2022.

The first safety-related concrete was poured for the nuclear island of Haiyang unit 3 in July 2022. Construction of Haiyang 4 began in April last year. The planned construction period for Haiyang 3 and 4 was 56 months, with the two units scheduled to be fully operational in 2027.

Naarea advances development of molten salt reactor fuel

_66787.jpg)

The company is developing the XAMR, an advanced modular reactor, a molten salt fast neutron microreactor capable of producing 40 MWe of electricity/80 MWt of heat that will burn plutonium and by reusing long-lived nuclear waste help close the fuel cycle.

The XAMR uses sodium chloride (NaCl), in which actinides in the form of plutonium chloride and uranium chloride are dissolved. In the absence of an industrial sector to supply fuel for these innovative technologies, the synthesis of fuel salt is a key step for validating the project's feasibility. This involves developing a reproducible synthesis method to produce a pure fuel salt containing fissile materials.

Since 2024, through its joint laboratory – the Innovation Molten Salt Lab (IMSLab) – with the French National Centre for Scientific Research (CNRS) and Paris-Saclay University, Naarea has been working with the European Commission's Joint Research Centre (JRC) on the synthesis of NaCl-PuCl3 salt.

The focus of this collaboration is on validating a proliferation-resistant method of synthesising NaCl-PuCl3 salt from plutonium oxide (PuO2), via a pyrochemical process, as well as experimentally determining fundamental data related to this fuel. This strategic method, proposed by Naarea, is based on a process that involves bubbling gas through a mixture of NaCl and PuO2, brought to a high temperature. This process is implemented thanks to specific experimental equipment developed and operated by the JRC.

Naarea said that, at laboratory scale, this work demonstrated that bubbling a gas through a mixture of NaCl and PuO2 made it possible to quantitatively dissolve the plutonium oxide to form a plutonium chloride-based salt.

"Additional characterisation stages will follow to confirm the purity of the fuel salt and determine its fundamental properties, which is vital to the development of the molten salt reactor industry," Naarea said.

It added: "This experimental validation work with plutonium represents an initial step in the fuel cycle strategy developed by Naarea, validating the synthesis method's feasibility and potential. Process engineering and scale-up tests will be carried out, in particular in the short term on simulants of radioactive materials in the experimental facilities of the I-Lab, Naarea's 2,400-square-metre test facility located in Cormeilles-en-Parisis."

Molten Salt Reactors (MSRs) use molten fluoride salts as primary coolant, at low pressure. They may operate with epithermal or fast neutron spectrums, and with a variety of fuels. Much of the interest today in reviving the MSR concept relates to using thorium (to breed fissile uranium-233), where an initial source of fissile material such as plutonium-239 needs to be provided. There are a number of different MSR design concepts, and a number of interesting challenges in the commercialisation of many, especially with thorium.

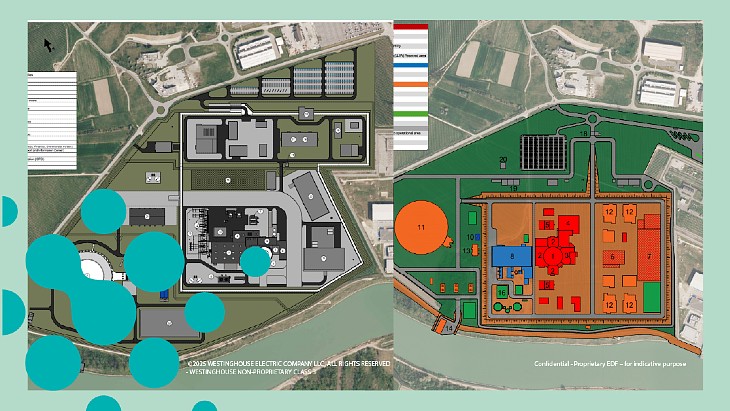

Westinghouse and EDF reactors both suitable for Slovenia project

It also said the "estimated investment amount is also within the framework of the value of the economic study of the JEK2 project, prepared by GEN energija in 2024" - these ranged from EUR9.314 billion (USD10.1 billion) for a 1000 MW unit and up to EUR15.371 billion for a 1650 MW unit.

Slovenia's JEK2 project is for a new one or two-unit nuclear power plant, with up to 2400 MW capacity, next to Krško NPP which has a 696 MWe pressurised water reactor generating about one-third of the country's electricity. Krško is owned and operated by Nuklearna Elektrarna Krško, which is jointly owned by Croatia's Hrvatska elektroprivreda (HEP Group) and Slovenia's GEN Energija.

In January Westinghouse and EDF were each asked to conduct a Technical Feasibility Study for their reactors at the site. Those have now been published by JEK2.

Vinko Planinc, Head of New Nuclear Facilities for GEN energija, said the studies confirm that the designs "allow for safe and efficient placement in the existing environment, taking into account the requirements for flood and earthquake hazards and with the possibility of minor adjustments".

JEK2 added: "Both technologies envisage cooling with a cooling tower using natural draft, which represents the most environmentally acceptable solution with minimal impact on the Sava River and the smallest carbon footprint." The EPR tower frame height would be 195 metres, the AP1000 approximate tower height 180m, JEK2 said.

It says that both firms are offering a power plant with a design life of 60 years, with extension to 80 years possible. Both companies have said they can build their standard power plant, adapted to the specific requirements of the site, but "to further reduce the risks in the project, both bidders recommend that additional studies be conducted that will enable a higher quality bid preparation with fewer uncertainties on the part of both the bidder and the investor".

Preparations for the JEK2 project have continued despite the postponement last year of a planned referendum on the plan. The indicative timeline is a Final Investment Decision in 2029, with construction beginning in 2033 and commercial operation in 2041.

In a press conference updating on progress, Bruno Glaser, Business Director of GEN energija, said public consultation and information events related to the national spatial plan are taking place until the end of September. A radiological study is being carried out with a report due in October, and public procurement for a Seismic Hazard Study is taking place.

The company also presented an overview of the economics of the project, with Gen energija putting the lowest economically viable cost of electricity from JEK2 as EUR70.2/MWh. It said that an estimate of EUR107/MWh produced by Youth for Climate Justice was higher "primarily from different assumptions regarding the cost of capital". The company also stressed the wider economic benefits for the country’s and the region’s economy.

Slovenia had been due to hold a referendum on new nuclear in November 2024, but that was called off amid a political row over how it was being conducted. Prime Minister Robert Golob said he remained committed to holding a referendum before a final investment decision is taken - which is currently due to be in 2028. There had initially been a third expected bidder in the process - Korea Hydro and Nuclear Power - but it pulled out before it moved to the Technical Feasibility Study stage.

Oklo announces plans for Tennessee fuel recycling plant

Oklo Inc has announced plans to design, build, and operate a facility at Oak Ridge in Tennessee to recycle used nuclear fuel into fuel for fast reactors like the company's own Aurora powerhouse, and is teaming up with TVA to look into recycling the utility's used fuel.

_35510.jpg)

The fuel recycling facility will be the first phase of a USD1.68 billion advanced fuel centre, the company said.

It is also exploring opportunities with the Tennessee Valley Authority (TVA) to recycle the utility's used fuel at the new facility and to evaluate potential power sales from future Oklo powerhouses in the region to TVA, a collaboration which Oklo says would be the first time a US utility "has explored recycling its used fuel into clean electricity using modern electrochemical processes".

"Fuel is the most important factor in bringing advanced nuclear energy to market," said Oklo co-founder and CEO Jacob DeWitte. "By recycling used fuel at scale, we are turning waste into gigawatts, reducing costs, and establishing a secure US supply chain that will support the deployment of clean, reliable, and affordable power. Tennessee is showing the nation that recycling can be done to support new nuclear development and growth."

Oklo said it has completed a licensing project plan for the fuel recycling facility with the US Nuclear Regulatory Commission (NRC) and is currently in pre-application engagement with the regulator's staff.

The Aurora powerhouse is a fast neutron reactor that uses heat pipes to transport heat from the reactor core to a supercritical carbon dioxide power conversion system which can generate both electricity and usable heat using fuel made from either fresh high-assay low-enriched uranium or used nuclear fuel. Oklo is planning to build its first Aurora powerhouse on a site at Idaho National Laboratory for which it has previously said it intends to submit a combined construction and operating licence application to the NRC later this year. Oklo is one of the 11 initial companies selected by the Department of Energy for support through the Nuclear Reactor Pilot Program, which aims to see at least advanced reactor projects achieve criticality in less than one year from now.

Attendees at the announcement of the planned advanced nuclear fuel centre included state and federal representatives (Image: Oklo Inc)

More than 94,000 tonnes of used nuclear fuel is currently stored at US nuclear power plant sites, and these contain considerable reserves of recyclable fuel. The fuel recycling facility will be the first phase of a multi-facility campus aimed at supporting recycling and fuel fabrication, Oklo said.

The US government halted reprocessing of used fuel from commercial reactors in 1977, as part of its stance against nuclear proliferation, but there have been several policy shifts since the early 2000. The Executive Orders signed by President Donald Trump earlier this year included directions to the Department of Energy to bring forward national policies on the management of used fuel and high-level waste and evaluate private-sector reprocessing options, amongst other things.

Government-owned TVA is the largest public power company in the USA, with a diverse generating portfolio including nuclear, hydro, coal, gas, solar and advanced technologies. Earlier this year, it submitted an application for a permit to construct an SMR at Clinch River, near Oak Ridge, using GE Vernova Hitachi Nuclear Energy's BWRX-300 technology. More recently, it has signed a collaborative agreement with ENTRA1 Energy to deploy up to 6 GW of NuScale SMR capacity, and has also signed a power purchase agreement with Kairos Power for up to 50 MW of electricity from Kairos Power's Hermes 2 demonstration reactor, which is to be built at Oak Ridge.

"The next generation of nuclear technologies are being built and developed right here in our own backyard," said TVA President and CEO Don Moul. "Our partnership with Oklo represents yet another step forward in shaping the future of nuclear energy and ensuring a secure energy future for the Valley and beyond."

The facility in Tennessee is expected to begin producing metal fuel for Aurora powerhouses by the early 2030s, following regulatory review and approvals, the company said.

French, Belgian industry groups agree to enhance cooperation

_77097.jpg)

"This agreement is part of a shared vision on the need to develop nuclear energy in order to meet the climate and energy sovereignty challenges facing both countries, as well as the European Union," the Belgian Nuclear Forum (BNF) said.

Under the agreement, BNF and Groupement des Industriels Français de l'Energie Nucléaire (Gifen) plan to strengthen their cooperation by implementing several concrete actions in the coming months. These include: information-sharing sessions on French and Belgian nuclear programmes and best industrial practices; exchanges between respective members to promote alliances and partnerships between the French and Belgian nuclear industries; joint actions to reaffirm the essential role of nuclear energy in contributing to the fight against climate change; and alliances to strengthen the path towards nuclear development at European level.

In 2022, French President Emmanuel Macron announced that the time was right for a nuclear renaissance in France, saying the operation of all existing reactors should be extended without compromising safety and unveiling a proposed programme for six new EPR2 reactors, with an option for a further eight EPR2 units to follow.

In May this year, Belgium's federal parliament voted by a large majority to repeal a 2003 law for the phase-out of nuclear power and banning the construction of new nuclear generating capacity.

In July, the energy ministers of France and Belgium signed a declaration of intent for the two countries to deepen their cooperation on nuclear energy. The declaration aims to strengthen exchanges between the two governments in key areas, including: the extended operation of existing reactors; the development of new projects, including small modular reactors (SMRs); research and innovation; strategic supply chains; training and skills.

"This cooperation agreement between sector federations, the BNF and Gifen, is a logical next step, as it is ultimately the industrial players who must put it into practice," said BNF Managing Director Serge Dauby. "Belgium and France can learn from each other and strengthen each other in various areas. Strategic cooperation such as this will be important in restoring nuclear energy to its rightful place at European level, where it can provide a response to long-term strategic challenges: security of supply, energy sovereignty and decarbonisation."

Olivier Bard, General Delegate of Gifen, added: "France and Belgium have historically been two of the driving forces behind the development of civil nuclear energy in Europe. The joint declaration signed in July by our two governments confirms a shared vision for the future of nuclear energy in our two countries and within the European Union. With today's signing of this agreement, the BNF and Gifen, as representatives of industry, are committed to implementing joint actions to promote the performance and development of nuclear companies."

No comments:

Post a Comment