‘Winter fishing on the ice of the Assiniboine and Red Rivers,’ by Peter Rindisbacher, 1821.

Published: December 7, 2022

THE CONVERSATION

With rising prices caused by inflation, Canadians are struggling to afford the basic costs of living. According to a recent Angus Reid Institute study, nearly 60 per cent of Canadians are struggling to provide food for their families. Meanwhile, profits are surging for grocery retailers, raising concerns about monopolies.

In today’s market economy, competition means standing out by offering customers more while working faster for less cost. Among top grocery retailers in Canada like Loblaws, Sobeys and Metro, it also means protecting and growing their dominant market position. The pandemic and other global crises has been especially profitable for the food business sector.

There is nothing new or surprising about the lengths corporations will go to maintain market dominance. Canada has a long history of big business antics, stretching as far back as pre-Confederation fur trade.

Building customer loyalty

In 1670, Charles II granted one company exclusive privileges to exploit the area around Hudson Bay. For a century, bayside factories bustled with trade activity, where Hudson’s Bay Company men operated as a type of trader know as factors.

The fur trade was about more than exchanging goods — it was about building loyalty. Speeches and gift exchanges stretched over multiple days, practices that reflected the customs of the Indigenous societies participating in the commercial trade. These were required if HBC factors wanted access to the goods and for Indigenous traders to return the next season.

Such practices created shared obligations between the parties, although this did not stop factors from shorting Indigenous traders. By applying the “factor’s standard,” company traders could demand more from Indigenous traders for less than was customary, or offer worse quality items in exchange for the usual quantity of furs.

It was risky — accusations of cheating left the company with more than dissatisfied consumers, it could cause productivity problems if the Indigenous party refused to return in the future. After all, in addition to gifts and consumer goods, the items Indigenous traders received were a type of compensation for their labours and fostered social relations.

Collusion and control

When trade shifted inland in the 1770s, the factor’s standard shifted too. The HBC was in direct competition with the Montreal-based North West Company, and each side tempted Indigenous traders away from their rival by offering more in quantity or quality.

By the early 1800s, this became an expensive rivalry. Company men acted in ways that appeared contrary to their bottom lines, driven by the desire to deny the other company profit.

Yet amid what seemed like mutually assured destruction, the rivals conspired to blacklist workers who deserted them, floated the idea of an informal collusion, and secured legal protections and advantages from government officials in Canada and Britain (including the military). Short term losses were nothing compared to long term gains in control.

Eventually, in an ultimate attempt to exercise control, the HBC established the Red River Colony (present-day Winnipeg) in 1812. Still dependent on Indigenous Peoples’ labour and allyship, this attempt to control Indigenous Peoples’ lands shows us how far the HBC would go to flex and protect their privileges.

Still building loyalty

Even though today’s market economy has changed a lot since the heyday of chartered monopolies, there are some similarities when it comes to company tricks and concerns about loyalty.

Faced with shrinking portion sizes and frozen or increased prices, consumers today are frustrated by “shrinkflation.” Some retail experts label shrinkflation a “consumer perception” problem, which becomes a loyalty problem when consumers feel cheated. Described by economics journalist Abha Bhattarai as “retail camouflage,” tricks like this are not necessarily illegal, but they can destroy consumer trust.

In October, Loblaw Companies president Galen G. Weston responded to customer outcry against grocery prices. This involved circulating a personalized note announcing a three-month price freeze on one of the company’s own brands.

With this note, Weston tried to appear as a compassionate voice for corporate decision-making. He volunteered to share the burdens by sacrificing profits, and seemed to recognize some sense of duty while still managing to stop short of a mea culpa.

More collusion and control

Instead of increasing customer loyalty, Weston’s public relations move backfired — much like the short-lived “hero pay” for employees (now recognized as a collusive wage-fixing practice). While these PR moves might have been well intentioned, they demonstrate a clear disconnect between grocery store chains and the needs of their customers.

Weston’s note suggested that companies like Loblaws can decide food costs at will, which undercuts claims that prices rose for reasons beyond their control, like rising supplier costs. It also turns out that price freezes are not that special, although Loblaws framed it that way. In the industry, it is routine for prices to remain relatively stable through the winter.

These antics are the latest in Canada’s long history of monopolies using questionable practices to protect their dominant position in the market. When considered alongside pre-Confederation fur trade, we see that market dominance is about control, which is the cornerstone of settler colonialism itself.

Associate Professor in Legal Studies, St. Jerome's University, University of Waterloo

Disclosure statement

Susan Dianne Brophy received funding for her book from the Canadian Federation for the Humanities and Social Sciences, Awards to Scholarly Publications Program.

Vogtle 4, left, and Vogtle 3, pictured in October (Image: Georgia Power)

Vogtle 4, left, and Vogtle 3, pictured in October (Image: Georgia Power).jpg?ext=.jpg) (Image: Kairos)

(Image: Kairos).jpg?ext=.jpg) A vial of the finished TRISO fuel particles (Image: BWXT)

A vial of the finished TRISO fuel particles (Image: BWXT).jpeg?ext=.jpeg) Illustration of a lunar base with a dome structure, research modules, observation pods and communication satellite dishes (Image: NNL)

Illustration of a lunar base with a dome structure, research modules, observation pods and communication satellite dishes (Image: NNL) The crane is called 'Big Carl' (Image: EDF)

The crane is called 'Big Carl' (Image: EDF)

The liner ring was prefabricated on-site (Image: EDF)

The liner ring was prefabricated on-site (Image: EDF) The 'Big Carl' crane, pictured in 2019 (Image: EDF)

The 'Big Carl' crane, pictured in 2019 (Image: EDF)-Ltd).jpg?ext=.jpg)

The decision was taken to lift the module already installed in the machine pit and disassemble it in order to proceed with the repairs (Image: ITER)

The decision was taken to lift the module already installed in the machine pit and disassemble it in order to proceed with the repairs (Image: ITER)

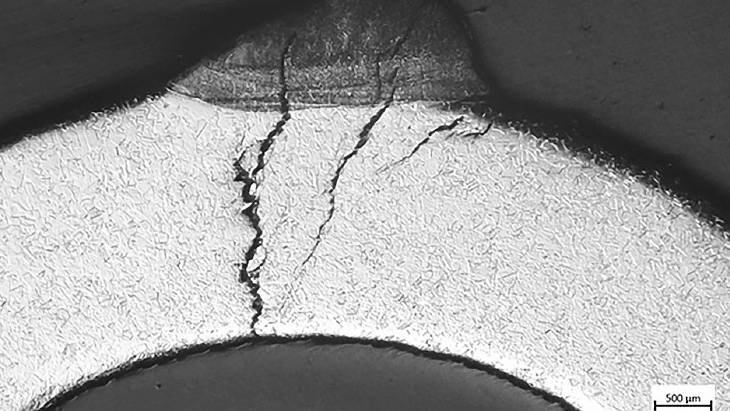

Investigative techniques (high-resolution CT scanning, scanning electron microscope, energy-dispersive X-ray spectrometer, and metallographic observation) revealed cracks in thermal shield cooling pipes such as the ones pictured here, 2.2 mm deep and crossing the full width of the pipe (Image: ITER)

Investigative techniques (high-resolution CT scanning, scanning electron microscope, energy-dispersive X-ray spectrometer, and metallographic observation) revealed cracks in thermal shield cooling pipes such as the ones pictured here, 2.2 mm deep and crossing the full width of the pipe (Image: ITER)

.jpg?ext=.jpg) The existing Borssele nuclear power plant (Image: EPZ)

The existing Borssele nuclear power plant (Image: EPZ)