The two spacecraft landed on Mars in January 2004, giving scientists the first evidence the red planet once held water.

By Jack Daleo

An artist’s concept depicts one of the twin rovers on the Martian surface. [Courtesy: NASA]

Two decades ago, a pair of NASA rovers changed the way scientists study Mars and the solar system forever.

January marks the 20th anniversary of twin rovers Spirit and Opportunity’s arrival on the Martian surface, where the vehicles searched for the first evidence of water on the red planet. Designed to last 90 days, Spirit was active until 2010, while Opportunity’s final communication came 15 years after landing.

Opportunity—nicknamed “the little rover that could”—was built to travel 1,100 yards but ultimately zigzagged nearly 30 miles across the Martian surface, covering a marathon-length distance by 2015. The rover finally succumbed to a planetwide dust storm in 2018.

“This was a paradigm shift no one was expecting,” said John Callas, former project manager of NASA’s Jet Propulsion Laboratory (JPL), which managed the Mars Exploration Rover mission, in a media release commemorating the anniversary. “The distance and time scale we covered were a leap in scope that is truly historic.”

[Courtesy: NASA Jet Propulsion Laboratory]

Before Spirit and Opportunity, scientists had no definitive proof that the network of channels visible from Mars’ orbit were formed by liquid water. The twin rovers delivered it—and set the stage for later and future explorations.

The Search for Life

The golf cart-sized twin rovers touched down three weeks apart on opposite sides of Mars: Spirit landed on January 3, while Opportunity followed on January 24. They arrived draped in airbags, bouncing along the surface dozens of times before coming to a stop.

Immediately, the rovers got to work snapping panoramic images—these were beamed back to scientists, who used them to select targets to investigate. Five-foot-high, mast-mounted cameras gave the vehicles a 360-degree, two-eyed, humanlike view of the terrain

The rovers’ robotic arms moved like a human’s with elbows and wrists. They could position instruments directly up against rock and soil scientists chose to investigate. A mechanical “hand,” meanwhile, held a microscopic camera that functioned like a geologist’s magnifying glass. A Rock Abrasion Tool (RAT) acted as a hammer, exposing the insides of rocks.

Spirit and Opportunity ultimately returned more than 217,000 raw images, illuminating the Martian surface like never before. Shortly after landing, Opportunity discovered Martian “blueberries”—spherical pebbles of mineral hematite that formed in acidic water. Spirit years into its mission unearthed evidence of ancient hot springs, which may have housed microbial life billions of years ago

Over the course of their mission, the twin rovers found that Mars not only supported fresh water but also hot springs and even acidic and salty pools at different points in its history. The findings were—and still are—considered groundbreaking.

“Our twin rovers were the first to prove a wet, early Mars once existed,” said Matt Golombek, former project scientist of the JPL. “They paved the way for learning even more about the red planet’s past with larger rovers like Curiosity and Perseverance.”

Lasting Legacy

Opportunity’s final transmission came in 2018. But the twin rovers’ impact will last forever.

“It is because of trailblazing missions such as Opportunity that there will come a day when our brave astronauts walk on the surface of Mars,” said former NASA Administrator Jim Bridenstine. “And when that day arrives, some portion of that first footprint will be owned by the men and women of Opportunity and a little rover that defied the odds and did so much in the name of exploration.”

NASA engineers’ work on Spirit and Opportunity unlocked practices for exploring Mars that continue even today, such as the use of specialized software or 3D goggles. Their experience countering roadblocks along the mission—of which there were many—has helped them plan safer, longer drives. It also allowed teams to quickly put together the more complex daily plans required to operate two later NASA rovers, Curiosity and Perseverance.

NASA approved the development of the SUV-sized Curiosity “thanks in part to the science collected by Spirit and Opportunity.” Its 2012 mission determined that the chemical ingredients needed to support life were present on Mars billions of years ago, when the red planet is thought to have been painted blue by water.

Perseverance landed on Mars in 2021 on a mission to collect rock cores to return to Earth. The project to check for signs of ancient life is part of a joint NASA and European Space Agency (ESA) campaign called Mars Sample Return.

Perseverance carried with it NASA’s Ingenuity, an autonomous, remotely commanded Mars helicopter. Not long after, it made the first powered flight on another planet. Ingenuity has now flown more than 25 times, including a record-breaking flight spanning 2,000 feet at 12 mph. The diminutive rotorcraft earned the reader’s choice honor in FLYING’s 2022 Innovation and Editor’s Choice Awards.

Read More: 2022 FLYING Innovation and Editor’s Choice Awards

The career of Abigail Fraeman—who was a high school student when she was invited to JPL on the night of Opportunity’s landing—perhaps best encapsulates the lasting impact of the twin rovers.

Fraeman went on to become a Mars geologist, returning to JPL years later to lead the Opportunity science team. Now, the accomplished researcher serves as deputy project scientist for Curiosity. She is one of many who were deeply affected by Spirit and Opportunity’s accomplishments.

“The people who kept our twin rovers running for all those years are an extraordinary group, and it’s remarkable how many have made exploring Mars their career,” Fraeman said. “I feel so lucky I get to work with them every day while we continue to venture into places no human has ever seen in our attempt to answer some of the biggest questions.”

Twenty years after Spirit and Opportunity touched down on the Martian surface, Perseverance is one month away from entering its fourth year on the red planet. But NASA isn’t stopping there. The next step? The return of humans to the moon via the Artemis program, followed by the first steps on Mars charted by the agency’s Moon to Mars architecture.

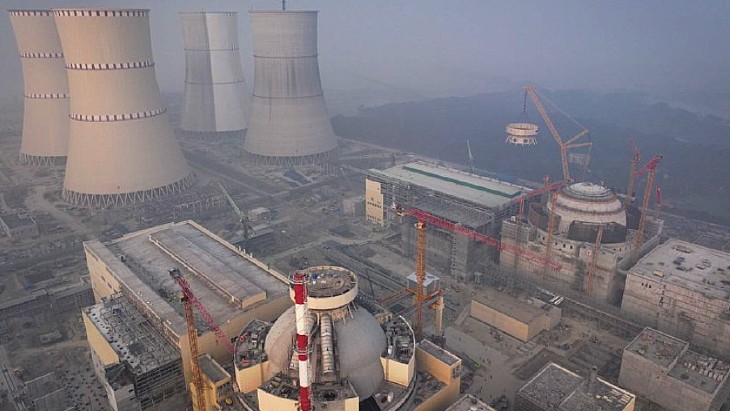

The structure sits on top of the reactor building (Image: Rosatom)

The structure sits on top of the reactor building (Image: Rosatom)

Workers on the top of the reactor dome helped with the precision task (Image: Rosatom)

Workers on the top of the reactor dome helped with the precision task (Image: Rosatom)

.jpg?ext=.jpg) The Barakah plant (Image: ENEC)

The Barakah plant (Image: ENEC).jpg?ext=.jpg) The continuous mining machine excavating Panel 11 at WIPP (Image: DOE Office of Environmental Management)

The continuous mining machine excavating Panel 11 at WIPP (Image: DOE Office of Environmental Management).jpg?ext=.jpg) The irradiated fuel's arrival at INL in December (Image: Businesswire)

The irradiated fuel's arrival at INL in December (Image: Businesswire) The IAEA director general at the UN (Image: UN Photo/Manuel Elías)

The IAEA director general at the UN (Image: UN Photo/Manuel Elías)