China Begins Patrolling Boundary of its "Nine-Dash Line" Claim

For the first time, China's coast guard has begun patrolling a section of the country's "nine-dash line" - the loosely-defined boundary of Beijing's unilateral claim to the South China Sea, including international waters and other states' exclusive economic zones.

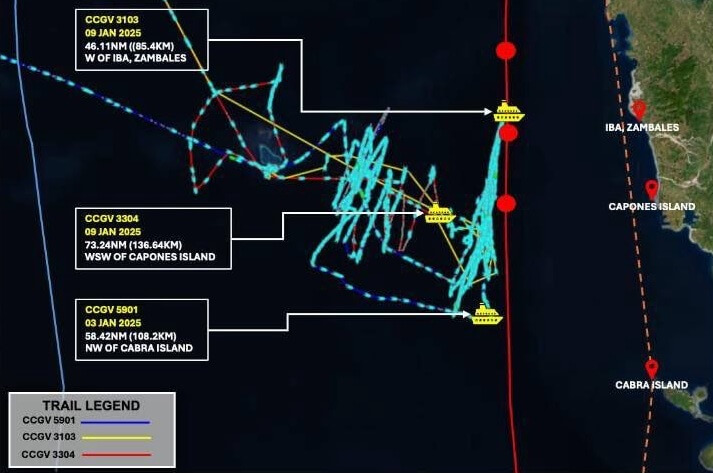

Since the beginning of the new year, a group of large China Coast Guard cutters have been rotating through patrol duty in an area just off Zambales, Luzon. At closest approach, the patrols have come within about 55 nautical miles of Philippine shores.

One of the deployed vessels is CCG 5901, the largest armed law enforcement vessel in the world at 12,000 tonnes displacement. Over VHF, its crew has informed the Philippine Coast Guard that the CCG is enforcing Chinese law in Chinese waters, even when 100 nautical miles inside the Philippine exclusive economic zone.

The Philippine Coast Guard has dispatched the offshore patrol vessel BRP Teresa Magbanua to monitor the Chinese presence and push back on these sovereignty claims. Despite rough weather conditions, the crew of the Magbanua have kept watch and demonstrated continued Philippine presence.

While monitoring the Chinese flotilla, the Philippine Coast Guard noticed a pattern that may explain the China Coast Guard's new behavior. The CCG cutters have been patrolling a north-south racetrack off Luzon's coast, and the tracklines align well with a segment of the "nine-dash line," which was invalidated by the Permanent Court of Arbitration in the Hague in 2016.

Courtesy PCG

"Their goal is to normalize such deployments, and if these actions go unnoticed and unchallenged, it will enable them to alter the existing status quo. This strategy of normalization, followed by altering the status quo and ultimately operationalizing their illegal narrative, has consistently been part of the Chinese playbook," said PCG spokesman Jay Tarriela. "This is why it is important for the Philippine Coast Guard to actively expose these unlawful deployments of Chinese vessels to the global community, ensuring that such actions are not normalized and that this bullying behavior does not succeed."

Tarriela warned that if China does not get pushed back, it could begin conducting the same patrols in other nations' exclusive economic zones, since the "nine-dash line" affects all of the coastal states of the South China Sea. This includes waters administered by Vietnam, Brunei, Malaysia and Indonesia.

To the north, South Korea's government is eyeing new Chinese activity in a contested part of the Yellow Sea. The so-called Provisional Measures Zone is claimed by both sides, and all activities within it are banned except for navigating and fishing. Construction is specifically disallowed - but China has been installing large metal structures in the zone, which it describes as "fishing support facilities." Another structure recently went in the water, South Korean officials reported January 9.

East Asian defense analysts have noted that China pursued a similar incremental strategy with its island-building campaign in the South China Sea - creating nominally civilian structures, militarizing them over time, and then using them to support political claims of sovereignty.

“China is not only installing structures but also conducting military exercises in the region, signaling its ambitions to establish effective control over the West Sea,” Lee Dong-gyu, a research fellow at the Asan Institute for Policy Studies, told Chosun Daily. “These actions aim to gain leverage in future negotiations with South Korea.”

White House Formally Blames China for "Unreasonable" Maritime Subsidies

China is by far the world's dominant shipbuilding nation, and the latest numbers from its industry ministry show that the lead has only widened. About 56 percent of all tonnage delivered worldwide came from China last year. Amidst a global boom, China now holds about 63 percent of the world orderbook, and its yards raked in an astonishing 74 percent of new orders over the course of the year. By certain measures, China also leads in ownership: about 19 percent of the global fleet is now Chinese-owned (and growing).

This has not gone unnoticed in Washington, and awareness of the strategic risk of a Chinese-controlled maritime transportation system has risen in Congress and in the White House. On Thursday, four days before President-elect Donald Trump's inauguration, the Biden administration formally announced that Chinese dominance in the maritime industry "is unreasonable and burdens or restricts U.S. commerce," leaving it subject to action under Section 301 of the Trade Act. The announcement was widely expected and provides leverage for Trump to negotiate with Beijing as soon as he enters the White House.

"Today, the U.S. ranks 19th in the world in commercial shipbuilding, and we build less than five ships each year, while the PRC is building more than 1,700 ships," said U.S. Trade Representative Ambassador Katherine Tai in a statement. "Beijing’s targeted dominance of these sectors undermines fair, market-oriented competition, increases economic security risks, and is the greatest barrier to revitalization of U.S. industries."

In a comprehensive report, the office of the USTR laid out how Beijing's intention to create a dominant maritime sector is "unreasonable." The office argues that the Chinese government has extraordinary control over investment decisions with Chinese bankers and lead players in Chinese shipping, like state-owned COSCO and CSSC, the world's largest shipowner and largest shipbuilder (respectively). USTR argues that this control is used to subsidize state shipping enterprises, estimated by independent studies as somewhere in the range of $11-16 billion per year in 2006-18.

The exact scale of China's government subsidies are hard to determine, USTR found, because of opaque relationships between firms in the Chinese state's giant business portfolio. "This opaqueness allows for China to hide the true extent of government support to the maritime, logistics, and shipbuilding sectors," USTR concluded.

According to USTR, China's subsidies are intended to create global market dominance in shipping, shipbuilding and logistics. As a result, U.S. trade is "carried out on vessels made in China, financed by state-owned Chinese institutions, owned by Chinese shipping companies, and reliant on a global maritime and logistics infrastructure increasingly dominated by China."

In addition to the Chinese maritime enterprises who are direct recipients of aid, the ultimate beneficiaries include Chinese manufacturers and exporters, who have enjoyed subsidized freight rates that give them an extra competitive edge. The Chinese government's runaway success in this endeavor "deprives market-oriented businesses and their workers of commercial opportunities, and lessens competition and creates dependencies on the PRC, increasing risk and reducing supply chain resilience," USTR concluded.

America's allies have also felt the impact. One study examined by USTR concluded that shipbuilding subsidies enacted in 2006 accounted for the entire price advantage that Chinese shipyards held over Japanese and South Korean yards in the years thereafter.

Five American unions had petitioned USTR to take action, and in a statement they issued their thanks.

"By targeting global maritime, shipbuilding and logistics sectors, the Chinese Communist Party has systematically – and publicly – worked to dominate this vital sector, leaving us increasingly dependent on the PRC and its industries to meet our economic and national security needs," said United Steel Workers President David McCall in a statement. "Now, we have the opportunity to turn the tide, create good, community-supporting jobs across the commercial shipbuilding supply chain and restore American maritime capacity and power."

Chinese Nationals Charged With Smuggling "Pink Cocaine" to Australia

Australia's federal police force has charged a group of Chinese nationals with attempting to import more than half a tonne of illegal drugs through the Port of Melbourne, disguised within a consignment of industrial goods. The shipment allegedly included a large quantity of "pink cocaine," a designer mixture of the club drug MDMA and the tranquilizer ketamine.

According to the Australian Federal Police, five men - four Chinese nationals and one Sydney resident - were arrested Wednesday in connection with the scheme. Three were charged with alleged involvement in smuggling the drug consignment into the country, and two were charged with possessing precursors for making methamphetamine.

The bust started last year when AFP authorities intercepted a cargo from Italy at the Port of Melbourne. Concealed inside a containerized shipment of galvanized hooks, they found 420 kilos of MDMA pills, 120 kilo blocks of a suspected drug mixture and 80 kilos of methamphetamine.

The mixed substance tested positive for MDMA and ketamine, consistent with the ingredients of a valuable designer drug sold as "Tusi" or "pink cocaine." Further testing is planned to determine the nature of the substance, which is a niche product and may be worth as much as $100,000 per kilo on the Australian market.

Taken altogether, the estimated street value of the combined shipment was in excess of US$70 million.

The shipment was seized and swapped with inert substitutes to mimic the appearance of the illicit import, and the consignment was allowed to continue delivery. The goods (and the fake drugs) were delivered to an address in Brooklyn, Australia; the police allege that the consignment was later taken and moved to a facility near Sydney.

“Importing nearly half a tonne of MDMA into Australia is a significant criminal endeavor and demonstrates the insatiable appetite for illicit drugs in our country, and the lucrative market through which organized criminals seek to earn significant profit," AFP Commander Raegan Stewart said in a statement.

The other two Chinese nationals were identified during the investigation of the drug smuggling scheme. They were arrested in Sydney on Wednesday, and were charged with possessing methamphetamine precursors. One of them faces an additional charge of allegedly interfering with access to electronic records during an investigation.