U.S. and Australia Team Up to Counter China's Rare-Earths Dominance

Engagement between Australia and the United States on critical minerals has matured from technical cooperation into a strategic partnership, aligning resource security with clean energy and defense priorities. Both governments recognize the urgency of diversifying supply chains as China entrenches its dominance across critical mineral extraction and processing. US policy has so far delivered strong domestic signals and backed its producers, but outcomes of its recent allied contributions remain to be seen.

China’s 2023 export ban exposed allied dependence on its processing power, prompting a strategic shift. While the US shielded firms including MP Materials with price guarantees, Australian producers such as Lynas Rare Earths remained vulnerable to market swings. October’s US–Australia Critical Minerals Framework signals continued momentum in bilateral cooperation. However, it is part of a broader sequence of initiatives that have achieved limited success in reshaping supply chains toward greater diversity and sustainability.

From technical cooperation to strategic compact

This partnership has rapidly evolved. A 2019 agreement between Geoscience Australia and the US Geological Survey provided a foundation for joint mapping and mineral assessments. By 2022, the Net-Zero Technology Acceleration Partnership formalized cooperation around zero-emissions technologies and diversified supply chains.

A breakthrough came in May 2023 with the Climate, Critical Minerals, and Clean Energy Transformation Compact. This established ministerial-level task forces and joint investment mechanisms, deepening the integration of supply chain planning. By October 2024, cooperation extended into batteries, long-duration storage, and solar supply chains through the Clean Energy Ministerial Dialogue. In July, Washington announced a Quad critical minerals initiative, signalling a more coordinated—but still US-led—effort to reduce Chinese dominance.

More significantly, both the US and Australia are members of the Minerals Security Partnership, a US-led multilateral forum launched in 2022. The US is a G7 member and Australia is an endorsing partner, and each has supported the G7’s five-point plan on critical-minerals security.

US strategy in transition

China’s December 2023 ban on exporting rare earth extraction and separation technologies was a wake-up call. It highlighted just how reliant the US and its partners remain on Chinese midstream processing. Even Western-backed projects, such as Brazil’s Serra Verde heavy rare earths mine, still depend on China to refine product. Raw supply diversification is meaningless without processing capacity.

In July, US President Donald Trump reshaped Biden-era industrial policy. By scaling back parts of the Inflation Reduction Act, Trump’s One Big Beautiful Bill Act weakened incentives for electric vehicle uptake and reduced demand certainty for critical minerals. Without long-term offtake agreements, more projects could turn to Chinese financing, ironically reinforcing Beijing’s dominance just as Washington seeks to undermine it.

The US Department of Defense’s US$400 million investment in MP Materials provides a stark contrast. With a guaranteed minimum price nearly double China’s market rate, Washington showed that industrial policy can shield producers from market volatility and strategic manipulation. But the benefits have so far been ringfenced for US firms.

Australia’s opportunity and risk

Australia brings to the table what Washington needs: resource abundance, political stability and a proven record as a secure supplier. Yet Washington’s protectionist tilt risks eroding trust. The Trump administration’s March decision to reject a reciprocal access deal, which guaranteed US access to Australian minerals in exchange for relief on steel and aluminum tariffs, was a missed opportunity.

Canberra has signalled it will not wait indefinitely. Australian Minister for Resources Madeleine King has floated an Australian price floor for critical minerals. The move suggests a more assertive industrial strategy designed to keep value onshore and diversify partnerships if Washington remains narrowly focused.

Meanwhile, firms such as Lynas Rare Earths face an uneven playing field. While MP Materials enjoys guaranteed prices and Pentagon backing, Lynas must contend with volatile markets and Chinese oversupply. Unless US policy expands beyond its borders, allied producers may remain perpetually vulnerable.

The trajectory ahead

China’s export bans underscore that allies must move up the value chain, not just secure raw supply. The MP Materials deal proves that price guarantees can stabilize projects and protect against Chinese manipulation. Extending such mechanisms to allies would not only strengthen trust but also deliver the scale of supply diversification that Washington’s strategy requires.

In a marked shift, under the United States–Australia Critical Minerals Framework, announced on 20 October, both governments pledged over US$3 billion in joint investments within six months to advance projects valued at US$53 billion. The announcement follows a major milestone a month earlier, when the US made a historic investment in Australia’s critical-minerals sector through the US Export–Import Bank’s financing of RZ Resources’ Copi Project, the first US-backed Australian minerals venture in more than a decade.

As part of the agreement, the bank will issue US$2.2 billion in financing to unlock up to US$5 billion in total investment. In addition, the US Department of Defense backs construction of a 100-metric-ton-per-year gallium refinery at Alcoa’s Wagerup facility in Western Australia, developed with Japanese participation through the Japan Australia Gallium Associates, a joint venture between the Japanese Government and Sojitz Corporation.

Building on this momentum, the Australian government has committed a $100 million equity investment to the Arafura Nolans project in the Northern Territory, which is expected to supply about 5 percent of the world’s rare earths once it becomes operational.

Scale and coordination remain essential. Australia must move beyond isolated critical-minerals projects and develop an integrated corridor through Darwin with pre-structured offtake, pricing, and traceability frameworks aligned to US standards.

Looking ahead, the US–Australia framework could be broadened into a wider Indo-Pacific partnership that includes Japan, South Korea and India, leveraging each country’s strengths in processing, industrial capacity and market demand.

The challenge now is to turn investment pledges into integrated, resilient supply chains that extend across the Indo-Pacific and deliver lasting stability for all partners involved.

Alice Wai is a junior researcher at ASPI.

This article appears courtesy of ASPI and may be found in its original form here.

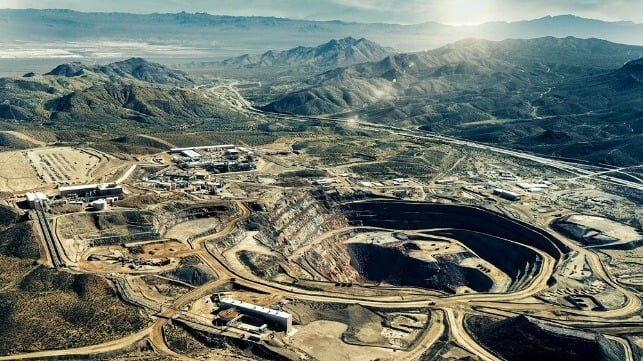

Top image: Mountain Pass Mine, California, 2022 (Tmy350 / CC BY SA 4.0)

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive

Marubeni to invest in Australian critical minerals project

Japan’s Marubeni Corp will invest in a mineral sands project owned by Australia’s RZ Resources, it said on Monday, following in the footsteps of compatriot JX Advanced Metals, which struck a similar deal with RZ earlier this year.

If the project’s feasibility is confirmed, Marubeni will contribute A$15 million ($9.75 million) for options granting it up to 5% equity participation in RZ’s Copi mineral sands mine project in New South Wales along with certain marketing rights.

RZ, which owns the Copi project and a mineral separation and processing plant in Brisbane, Queensland, plans to produce heavy mineral sands products such as rutile, ilmenite, zircon and monazite. These minerals are used in industries including aerospace, defence and permanent magnets.

Alternatives to China

The alliances come as Japan and its Western allies step up efforts to secure critical minerals supply chains outside China, which has been tightening export restrictions on key resources.

JX, a producer of advanced materials from copper and rare metals used in chips and telecommunications parts, became a strategic partner of RZ in June.

Marubeni, RZ and JX will jointly work on developing the Copi mine project, upgrading RZ’s mineral separation plant, and enhancing RZ’s definitive feasibility study and environmental impact statement, Marubeni said in a statement.

JX said in a separate release that its participation in the project aims to secure a long-term, diversified supply of minerals, including minor metals and rare earths. It also cited the project’s location in a geopolitically stable region with well-established transport infrastructure, including shipping routes.

The project has received expressions of support from the Export-Import Bank of the United States and the Export Finance Australia, it added.

“Through Marubeni’s participation, we expect to leverage its network to secure sales channels for minor metals and rare earths, which we believe will further advance the project,” JX said, adding that it plans to expand similar partnerships.

($1 = 1.5389 Australian dollars)

(By Yuka Obayashi; Editing by Muralikumar Anantharaman and Joe Bavier)

Ionic Rare Earths signs preliminary deal for US recycling plant

Ionic Rare Earths said on Monday it has signed a non-binding memorandum of understanding with US Strategic Metals to build a recycling facility that will produce rare earth oxides, including those subject to export restrictions from China.

The Missouri recycling facility is expected to produce significant quantities of neodymium and praseodymium (NdPr) as well as heavy rare earths including dysprosium, terbium, samarium, gadolinium, and holmium, the companies said in a joint statement.

The agreement focuses on rapidly producing high-purity, separated magnet rare earth oxides, with potential expansion to include a wide range of magnet and heavy rare earths from a range of strategically sourced mixed rare earth carbonates, the statement said.

“Magnet recycling is the fastest and lowest-cost pathway to developing an ex-China rare earth supply chain in the United States,” Ionic Rare Earths managing director Tim Harrison said.

Ionic Rare Earths said it was looking to replicate the capability it has demonstrated at its Belfast recycling plant to provide a strategic supply of magnet and heavy rare earths into the US supply chain.

The MOU comes after the US and Australia signed a wide-ranging critical minerals agreement last month with an aim of countering China’s hold over the industry.

(By Melanie Burton; Editing by Jamie Freed)

No comments:

Post a Comment