'The algorithm fired me': California bill takes on Amazon's notorious work culture

California lawmakers are taking aim at Amazon.

The bill, the first such legislation in the nation, would require warehouses to disclose quotas and work speed metrics to employees and government agencies. It would ban "time off task" penalties that affect health and safety, including bathroom use, and prohibit retaliation against workers who complain.An Assembly-passed bill is expected to reach the Senate floor this week or next to crack down on the opaque, algorithm-led and harsh warehouse work conditions often attributed to the Seattle technology behemoth.

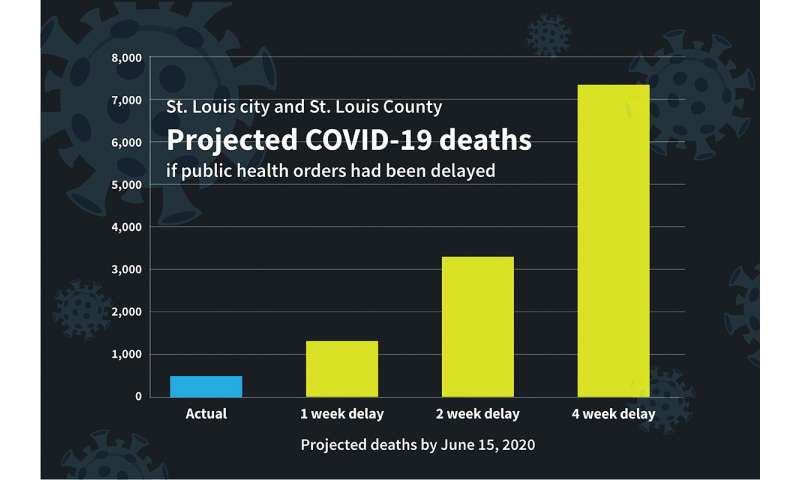

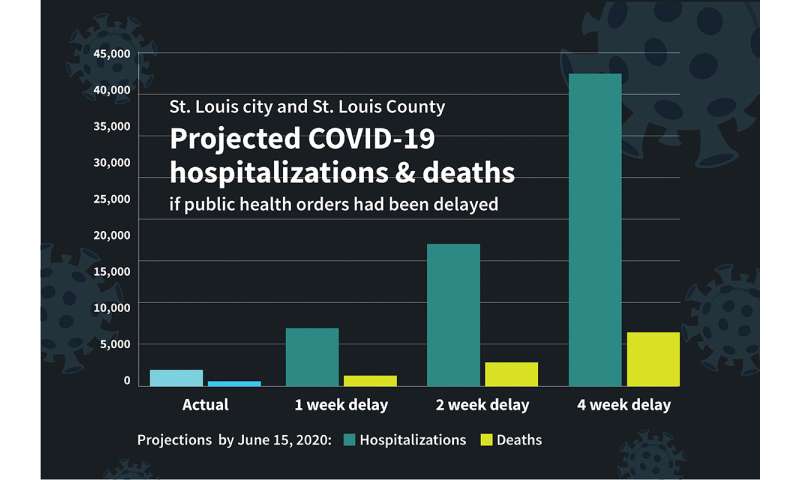

Amazon dominates online shopping across the nation amid a surge in e-commerce fueled by the COVID-19 pandemic. With 950,000 U.S. employees and $368 billion in revenue in 2020, it is the nation's second-largest employer after Walmart, and is under growing pressure to address worker injuries in its supply chain.

"Amazon has set the pace, creating a market for next-day delivery of consumer goods," said Assembly member Lorena Gonzalez (D-San Diego), the bill's author. "We see Walmart and other large warehouses following suit. We need to make sure our laws catch up with that."

California's workplace laws often influence other states and the federal government, experts say. The state Senate vote on the bill, AB 701, is expected to be close, amid heavy opposition from retailers and other industries.

Scholars see broad implications for the future of work. "In the U.S., we are at an inflection point on the question of how technologies are used in workplaces and what rights workers have to data collected about them," said Beth Gutelius, research director at the University of Illinois at Chicago's Center for Urban Economic Development and an authority on logistics.

"Warehouses are where the dark sides of work surveillance are being revealed."

In analyzing the legislation, the Senate Judiciary Committee cited studies showing Amazon's injury rate to be nearly twice that of the warehouse industry generally. One study compared Amazon's 2020 injury rate (6.5 injuries for every 100 workers) to Walmart's (three injuries).

"Amazon, at least, may have made the market-based decision that avoiding workplace injuries is more costly than maintaining the delivery speeds for which it is famous," the committee suggested.

Amazon and Walmart declined to comment on the legislation or to answer questions on their respective injury rates.

Amazon spokeswoman Rachael Lighty wrote in an email: "Like most companies, we have performance expectations for every employee, and we measure actual performance."

Amazon offers coaching to workers who don't meet targets, she said. "The truth is, terminations for performance issues are rare—less than 1%. The health and safety of our employees is our No. 1 priority."

In a letter to shareholders in April, Chief Executive Jeff Bezos wrote, "We need to do a better job for our employees." News reports portraying them as "desperate souls and treated like robots" are inaccurate, he asserted.

To address employees' sprains and strains from repetitive motions and prevent forklift and other industrial vehicle collisions, he wrote, Amazon will invest more than $300 million in safety projects this year.

Consumer demand is fueling rapid growth in warehouse work. In California, where imports from Asia flow through the ports of Los Angeles, Long Beach and Oakland to giant distribution centers, 209,700 warehouse workers were employed in July, nearly double the number five years ago.

The Inland Empire, spanning Riverside and San Bernardino counties, is the nation's biggest warehouse center. Amazon is the region's largest employer, with an estimated 40,000 logistics workers.

The state legislation ratchets up the pressure Amazon already faces from an energized labor movement. The company crushed a campaign in April to unionize 6,000 workers at one of its warehouses in Alabama. In June, the International Brotherhood of Teamsters announced a nationwide push to organize Amazon's delivery and warehouse employees, calling the company an "existential threat" to workers across the logistics industry.

Chanel Hawkes, 33, lost her job at a call center when her company closed during the pandemic. "Amazon was the only company that was hiring and thriving," she said.

At Amazon's Eastvale complex with 6,000 employees, she packed boxes of mouthwash, books and toys from 6 p.m. to 4:30 a.m. four or five days a week. She earned $15 an hour.

"I like a challenge," she said. "But it was like sprinting on your feet for 10 hours."

Soon, she felt intense pain in her wrist. Her supervisors, she said, told her to "eat more protein," do wrist stretches and get back to work.

Warehouse computers, which she checked three times a day, told her to make a "rate" of 70 to 80, a speed measure she said was never explained—and which Amazon declines to define publicly. She was working at a "rate" of only 50 to 60.

Hawkes asked for an easier job, telling supervisors "my nerves are hurting." It didn't happen. She was not referred to workers' compensation doctors, she said. And in March, after seven months, she was terminated.

Now she can't drive or push a grocery cart without feeling pain, she said. An art major in community college, she wonders when she will be able to paint again in her spare time.

"I was just a working woman," Hawkes said. "Especially being African American, I didn't know how to fight a big system."

Amazon did not respond to questions about Hawkes' experience.

Race is part of the debate over AB 701. Latino and Black employees constitute 66% of warehouse staff, although workers of color account for just 37% of the total U.S. labor force, according to a UC Berkeley study.

"These backbreaking conditions have significant implications for communities of color," the Los Angeles County Federation of Labor and other bill supporters wrote lawmakers this summer. "Many … feel they must accept unsafe conditions to keep a roof over their heads. [They] are least likely to have adequate health insurance or any safety net."

Yesenia Barrera, a former Amazon worker in Rialto, told an Assembly committee, "We are carrying, bending, reaching, twisting and packing items from 30 to 60 pounds for hours a day with no proper rest time."

After just one warning, she said, "The algorithm fired me, and other workers like me, though we were working as hard as we could."

Barrera, 22, has since gone to work as an organizer for the Warehouse Worker Resource Center, a foundation-funded nonprofit in Ontario that is backing AB 701.

"Workplace quotas have been around for centuries," said Sheheryar Kaoosji, the center's executive director. "We've seen high injury rates at Walmart too. But Amazon makes it much more burdensome with surveillance. Other companies would love to do what Amazon does—wire their facilities wall to wall."

California's general ergonomic standard is weak and rarely enforced, he said. At unionized warehouses, covering roughly 10% of workers, safety issues are bargained with management, but at Amazon and other nonunion facilities, "workers have no recourse, and they just feel lucky to have a job," Kaoosji said.

In a class-action lawsuit that Amazon settled in December, Trevion Sherman and 26 other California plaintiffs described how the company's "production clock does not stop when employees need to use the restroom" so they went without bathroom breaks for fear of termination.

Amazon declined to reveal the terms of the settlement.

A coalition of industries led by the California Chamber of Commerce has spent months lobbying against AB 701. "Productivity standards are not inherently punitive," the group wrote lawmakers Aug. 3. Nonetheless, after several clarifications to the bill, the chamber softened its opposition, removing it from its annual "job killer" list—a tag that often dooms legislation.

In further compromises last week, backers amended the measure to cut out a requirement for Cal/OSHA, the state's workplace safety agency, to adopt a warehouse-specific injury rule. Backers said the bill remains strong because it steps up enforcement by the state labor commissioner. New language also exempts farm facilities to prevent spoilage before shipping.

Republican lawmakers continue to oppose the legislation, saying it will raise consumer prices and burden companies with litigation.

Sen. Brian Jones (R-Santee) called it "part of a campaign to tip the scales to coerce employees to unionize," noting that AB 701 is backed by the Teamsters. Democrats, he said, should not be trusted to "micromanage private warehouses."

Amazon points to benefits that nonunion warehouses don't always offer, such as health insurance from the first day of employment.

That's what drew Nathan Morin, 33, to work in an Amazon warehouse in Redlands for three years as a packer, forklift driver and truck loader until December. He didn't have health insurance and was able to immediately sign on to a plan through Kaiser Permanente.

Another benefit was Amazon's policy of adjusting his schedule to fit around his college classes while he was a student at Cal Poly Pomona.

From the first day, Amazon "said it's a very physical job, but they never told us about the quotas," he recalled. "You were allowed 30 minutes 'time off task' a week. But the bathrooms are at the far ends of the warehouse. If you took 10 minutes to go once a day when you weren't on break, you would be written up at the end of the week."

Morin's packing quota was at least 70 items an hour during Amazon's peak seasons. "Cameras were at workstations, in break rooms, in locker rooms," he said. "Devices would flag managers if you took 'time off task.' It was dehumanizing."

Morin said he saw about a dozen workers get injured, including a woman who was told by an Amazon workers' comp doctor that she had pulled a muscle, only to find out later, she reported, that she had fractured her knee. "To this day, she can't walk right," Morin said.

At one point, Morin worked as a "learning ambassador" coaching struggling workers with tips to avoid a write-up. If injured employees were granted accommodations with lower-stress tasks, "It was like two weeks and then you were expected to go back to work," he said.

"You hoped they could work faster," he said. Otherwise, it was termination.

Amazon did not respond to questions about Morin's experiences.

Looking back, Morin said, "I don't want to think Amazon deliberately injures people. It is a product of the work culture—getting things done as quickly as possible."

©2021 Los Angeles Times. Distributed by Tribune Content Agency, LLC.