CRIMINAL CAPITALI$T ROBBER BARON

Elon Musk’s Starlink linked to illegal mining in Brazil

Jackson Chen | March 16, 2023 |

SpaceX’s starlink satellites stream across the sky in Brazil. Image source: Wikipedia.

Perhaps not even the biggest Elon Musk detractors could have imagined one of his ventures being linked to unethical mining.

Reports this week by The Associated Press revealed that illegal gold miners in Brazil’s Amazon have been using Musk’s Starlink high-speed internet technology as a novel tool for illicit operations.

Launched in 2019 as a division of SpaceX, Starlink is a low latency, broadband internet system consisting of nearly 3,600 low-orbit satellites that aims to connect the underserved areas of the planet with the rest of the world.

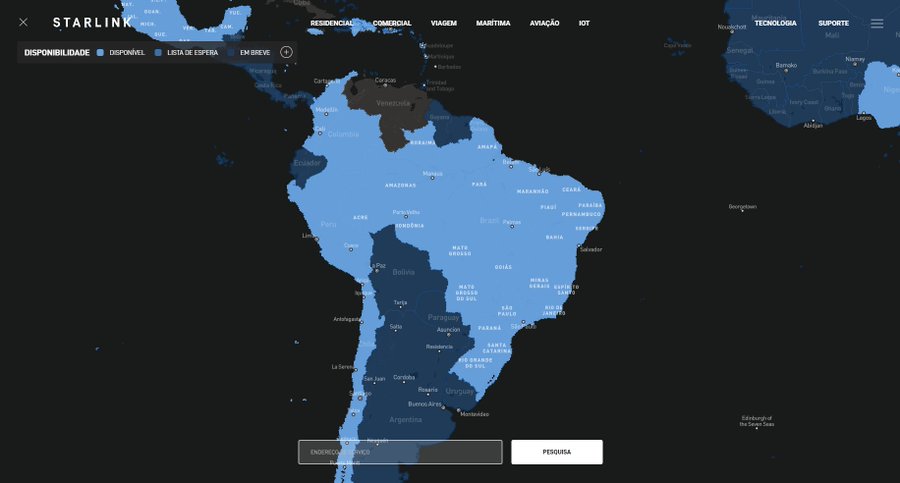

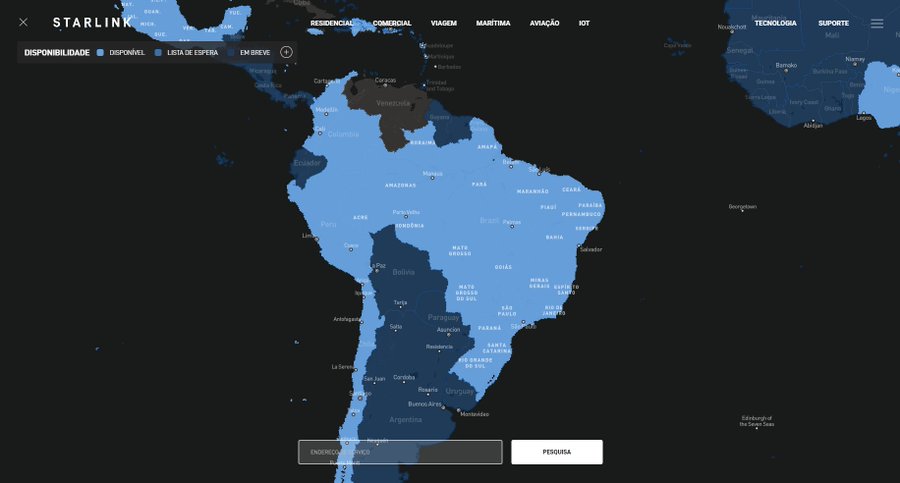

In Brazil, this technology was made available last January as part of a government-led project to serve schools in rural areas and monitor the Amazon rainforest. While that project has failed to gain traction, the use of Starlink has only grown across a region populated by illegal mining groups, according to reports.

Illegal miners have long relied on internet as a means for communication, but the logistics involved in setup and the luck needed for it to work without getting caught by law enforcement, would have been a gamble. So Musk’s Starlink may have been seen as a safer bet.

In a federal raid on an illegal mining site Tuesday, agents from the Brazilian environment agency’s special inspection group and the federal highway police rapid response group found one Starlink terminal up and running next to a pit, Associated Press reported.

Apart from the Starlink terminal, some mercury, less than an ounce of gold, camping and storage units among other mining and transportation equipment were reportedly seized.

The SpaceX-operated satellite is able to provide fast, stable internet service for coordinating logistics, receiving warning of raids, and making payments without having to fly to a city. The equipment is also easy to install and transport, making it the perfect tool for mining the Amazon.

“The benefits of connectivity were immediately apparent to bad actors in the Amazon,” Hugo Loss, operations coordinator for IBAMA, Brazil’s environment agency, told the Associated Press.

“This technology is extremely fast and really improves the ability to manage an illegal mine. You can manage hundreds of mining sites without ever setting foot in one,” he told AP.

When he took officer earlier this year, Brazil President Luiz Inácio Lula da Silva vowed to crack down on illegal mining in the country, in particular Yanomami land, its largest Indigenous territory. In recent years, it is estimated that around 20,000 prospectors have contaminated the region’s vital waterways with mercury used to separate gold, according to the AP

.

Starlink is now available throughout Brazil. Credit: SpaceX

Over the past five weeks, the nation’s environment agency has seized seven Starlink terminals in Yanomami land, including the two during the recent raid, the agency’s press office said in an emailed statement to AP.

“An untold number of the highly portable Starlink terminals could have been taken with miners as they fled sites into the rainforest,” it added.

IBAMA told the AP via email that it, along with other federal bodies, is currently studying how to block Starlink’s signal in illegal mining areas.

“This measure is crucial to dismantling the logistics that sustain illegal mining in Indigenous territories,” IBAMA’s press office said.

Whether any further action taken by Brazil’s authorities remains to be seen. What’s for certain is Starlink’s presence in the Amazon is posing a big challenge to President Lula’s mission to eradicate illegal mining.

Related Article: How wildcat mining is behind the Yanomami crisis in Brazil