American Rare Earths, Wyoming U team up on byproduct research at Halleck Creek

American Rare Earths (ASX: ARR), in partnership with the University of Wyoming, has been selected for a research award to examine and explore end-uses for the tailings and other byproducts resulting from rare earth elements production at the company’s Halleck Creek project.

The funding will be provided through the Accelerating Research Translation (ART) initiative funded by the US National Science Foundation (NSF), which aims to emphasize applied research innovations that have high potential for commercialization.

The AAR-UW partnership was selected for the Seed Translational Acceleration of Research (STAR) Project award, a core component of the NSF ART program specifically designed to advance innovations with validated commercial potential that can be completed in one year.

UW is part of the inaugural cohort of institutions to receive the NSF ART award, which provides $6.3 million in funding over four years.

“The intent is to fund projects on a milestone-driven basis with usable outcomes for the industry partner at the end of the project,” Parag Chitnis, UW’s vice president for research and economic development, said in a news release.

“These projects will serve as a basis for training graduate students and postdoctoral fellows, while simultaneously advancing tangible research that directly impacts development projects in Wyoming.”

Led by Tyler Brown, minerals program manager in SER’s Center for Economic Geology Research, the project team will work directly with Wyoming Rare to examine the tailings and byproducts resulting from rare earths extraction at Halleck Creek. They will also explore potential applications for those materials to determine potential technical viability for end-use applications, processing requirements and implications to overall project economics.

Last year, ARR reached a metallurgical milestone at the project when it upgraded ore from the tenure from 0.34% total rare earth oxides (TREO) to 3.72% TREO. The figure represented a ten-time increase in rare earth concentrate, and metallurgical tests showed that 93.5% of non-rare-earth material can be removed early, leaving only 6.5% of ore needing further refining, the company said.

Critical minerals firm weighs plan to build US rare earth plant

Atlantic Strategic Minerals, a small US mining company, is considering building a rare earths plant in a bid to join America’s push for domestic production of key materials.

The facility would be at the company’s operations in Stoney Creek, Virginia, about 150 miles from Washington, DC, where it already produces some critical minerals and rare earth elements as a byproduct, according to Michael Scherb, chief executive officer of Appian Capital Advisory, which owns Atlantic Strategic Minerals.

“We’re debating now what we should do with the byproduct,” Scherb said Tuesday in an interview. “You can separate it and you can produce rare earths, but you need a refining facility.”

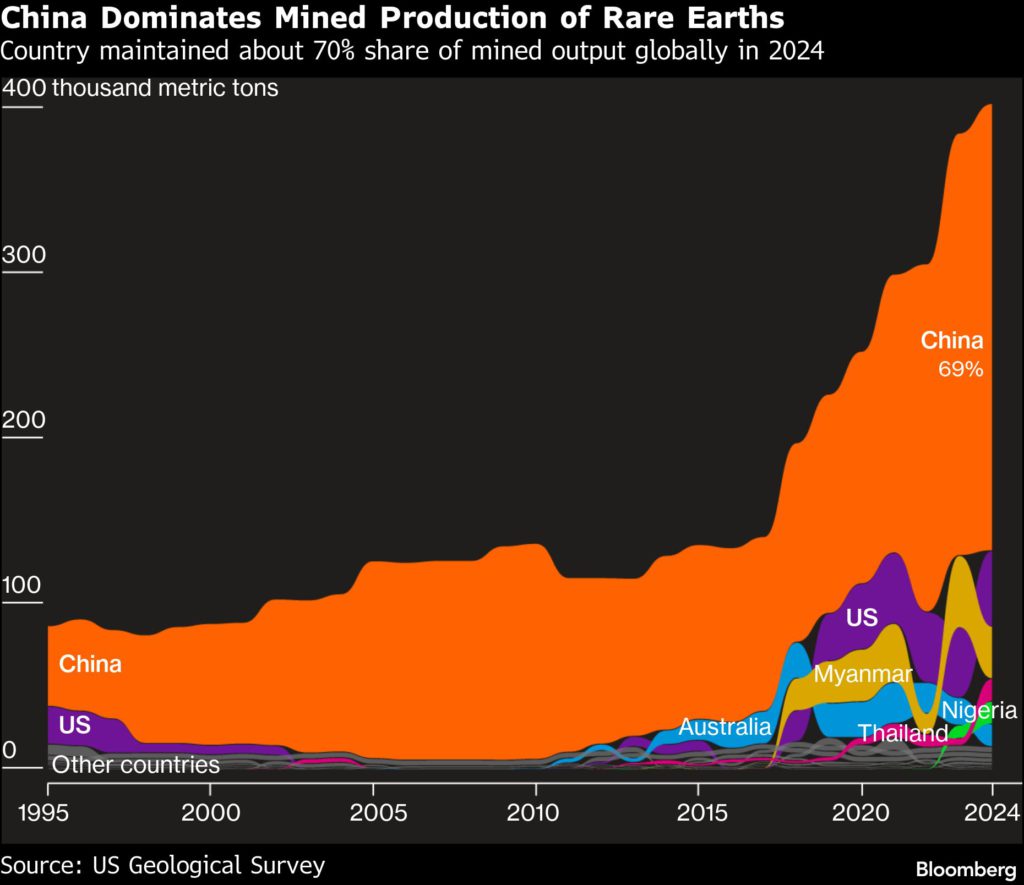

The decision follows the Trump administration’s push to loosen China’s grip on rare earth minerals, which are essential for products ranging from smartphones and electric vehicles to fighter jets. China controls the vast majority of the world’s rare earth mining and processing capacity, leaving US industries exposed to potential supply shocks.

Appian, which has about $5 billion of assets under management, is one of a few investment firms dedicated to the mining sector, alongside the likes of Orion Resource Partners and Resource Capital Funds. Atlantic Strategic Minerals started commercial operations in June, where it now produces niche minerals like ilmenite — a primary material used in titanium — and zircon, a source for the metal zirconium, which is used in nuclear reactors.

Scherb said Appian has held conversations with the White House seeking government support for the plant, which he estimated would cost under $100 million to build. The firm also is looking at processing domestic and international materials from third—party companies beyond its own operations, including Appian-owned Gippsland Critical Minerals, which has a rare earths project in Australia.

Companies have announced a flurry of investment plans for critical mineral projects in the US in light of President Donald Trump’s efforts to secure domestic supplies. Korea Zinc Co. — one of the world’s largest zinc processors — is planning a $7.4 billion smelter in Tennessee, while MP Materials Corp. is building a rare earths separation plan in California.

Atlantic Strategic Minerals’ facility would be considerably smaller but easier to achieve, said Scherb.

“These grand, huge mega-projects — you don’t need to pursue those,” he said. “You can actually look at more cost-effective, strategic ways to get supply out, whether it be through recycling or better use of the byproduct that comes out of operations like these.”

(By Jacob Lorinc)

No comments:

Post a Comment