KR, Korean Govt., and Partner Set Standards for Ammonia Effluent Discharge

[By KR (Korean Register)]

As the maritime industry accelerates its transition to zero-carbon fuels in line with the International Maritime Organization (IMO)’s 2050 net-zero target, ammonia-fueled ships are emerging as a promising next-generation solution. While the IMO has established interim guidelines to facilitate the use of ammonia as a marine fuel, international standards governing the safe treatment and discharge of toxic ammonia effluent generated during vessel operations have yet to be developed.

During the operation of ammonia-fueled ships, effluent containing toxic ammonia may be generated. Unlike typical aqueous ammonia, this effluent exhibits different physical and chemical characteristics, and the lack of clearly applicable international standards has created uncertainty for ship design, operation, and environmental management.

In response, KR (Korean Register), in collaboration with the Ministry of Oceans and Fisheries (MOF), five major Korean shipbuilders including HD Hyundai Heavy Industries, HD Korea Shipbuilding & Offshore Engineering, HD Hyundai Samho, Samsung Heavy Industries, and Hanwha Ocean, as well as the Korea Testing & Research Institute (KTR), officially launched an international working group in June 2025 to develop safety management and marine discharge standards for ammonia effluent.

The establishment of this joint working group followed Korea’s proposal at the IMO Sub-Committee on Carriage of Cargoes and Containers (CCC) in 2024, which highlighted the need for dedicated ammonia effluent safety standards. The proposal granted official approval at the 83rd session of the Marine Environment Protection Committee (MEPC) in April 2025.

To commence its activities for 2026, the working group convened on February 5 at the HD Hyundai Global R&D Center, reinforcing inter-organizational cooperation on the development of international standards. Over 2026 and 2027, the group plans to submit draft international standards to the IMO Sub-Committee on Pollution Prevention and Response (PPR), positioning Korea at the forefront of global discussions on ammonia effluent management.

At the upcoming 13th session of the IMO PPR, scheduled for later this month, the Korean government delegation will underscore the urgency of establishing guidelines for ammonia effluent management and marine discharge standards, and propose the formation of an Expert Group for in-depth technical discussions. KR is leading these international deliberations by providing technical evidence on safe discharge limits, based on its environmental impact assessment of ammonia effluent.

This international standards development initiative presents a significant opportunity to embed Korea’s shipbuilding technological capabilities and operational experience into global regulations. From a regulation-driven industrial development perspective, this will strengthen the competitiveness of the Korean maritime industry as the market of ammonia-fueled ships expands.

KR’s Executive Vice President, KIM Kyungbok, stated, “This year’s IMO meetings mark the beginning of substantive international discussions on ammonia effluent safety standards. Drawing on KR’s technical and regulatory expertise, we will play a leading role alongside the Korean government and industry to ensure that proven domestic technical standards are effectively incorporated into international rulemaking.”

NUS Project to Advance Near-Zero-Emissions Ammonia Marine Engines

[By National University of Singapore (NUS)]

Industry–academia collaboration to be based at the National University of Singapore’s College of Design and Engineering targets decarbonisation of the global shipping industry through new ammonia-fuelled engine concept

A major new research project to be located on the College of Design and Engineering (CDE) campus at the National University of Singapore (NUS) aims to accelerate the decarbonisation of the global shipping industry through the development of next-generation ammonia-fuelled marine engines with high efficiency and near-zero emissions.

Officially launched on 4 February 2026, the project is led by the NUS Centre for Hydrogen Innovations (CHI) with funding support from the Singapore Maritime Institute (SMI), in collaboration with leading academic and industry partners in Singapore and overseas. The project focuses on a novel in-cylinder reforming gas recirculation (IRGR) engine concept designed to address key limitations that have so far constrained the wider adoption of ammonia as a marine fuel.

“Ammonia has been recognised as one of the most promising fuels for achieving near-zero greenhouse gas emissions in marine transportation, but current ammonia engines face significant challenges in efficiency and emissions,” said Associate Professor Yang Wenming from the Department of Mechanical Engineering at NUS, who leads the project as Principal Investigator. “The IRGR concept is designed to address these limitations by improving combustion efficiency while sharply reducing unburned ammonia and other pollutants.”

“The project will be based in a dedicated laboratory on the CDE campus, featuring an engine test room, control room and facilities for fundamental combustion and systems research,” said Dr Zhou Xinyi, Senior Research Fellow from the Department of Mechanical Engineering. Beyond technical development, the initiative also aims to strengthen Singapore’s position as a hub for maritime innovation and sustainable shipping technologies by anchoring advanced engine research within a broader ecosystem of industry collaboration and talent development.

Speaking at the launch ceremony, Professor Silvija Gradecak, Vice Dean (Research and Technology) at CDE, described the IRGR Ammonia Engine Project as an important milestone for efforts to decarbonise the maritime sector.

“Marine transportation is central to global trade, yet it remains one of the most challenging sectors to decarbonise,” she said. “Through this project, the team aims to develop and demonstrate the world’s first prototype engine based on the IRGR concept, paving the way for the practical adoption of ammonia as a marine fuel.”

Global shipping currently accounts for approximately 3 per cent of global carbon emissions, and the sector faces increasing pressure to reduce its environmental impact in line with international net-zero targets. While ammonia does not produce carbon dioxide at the point of combustion and is easier to store and transport than hydrogen, challenges related to thermal efficiency, combustion stability and pollutant emissions remain critical barriers to commercial deployment.

International collaboration is a central feature of the IRGR project. “The International Maritime Organization’s net-zero emissions target must be achieved by 2050, and the time left is very short,” said Professor Li Tie from Shanghai Jiao Tong University, a key academic partner in the project. “This goal cannot be realised by any single institution or country. It requires disruptive technologies and strong international cooperation, and the IRGR project reflects exactly that kind of collaboration.”

The consortium includes partners from Shanghai Jiao Tong University, Nanyang Technological University, the A*STAR National Metrology Centre and Keppel Energy Nexus, alongside industry partners Daihatsu, a leading global marine engine manufacturer, and the American Bureau of Shipping (ABS). Their involvement is intended to ensure the research remains grounded in practical engineering requirements, safety considerations, certification pathways and commercial relevance.

The launch event at NUS was attended by senior representatives from the government, industry, and academia, including leaders from SMI and the Maritime and Port Authority of Singapore, as well as the President of Daihatsu Infinearth, Mr Yoshinobu Hotta, and Vice President of ABS, Dr Gu Hai. The event also included the formal signing of research collaboration agreements between NUS and Daihatsu, and between NUS and ABS.

Closing the event, Professor Lee Poh Seng, Head of the Department of Mechanical Engineering, emphasised the broader significance of the initiative.

“This project is not merely the start of another research programme, but a deliberate step into one of the hardest and most consequential engineering challenges in the energy transition,” he said. “Decarbonising hard-to-abate sectors like shipping requires technologies that can be validated, scaled and trusted in real-world operations.”

The project is expected to run for three years, with the research team working towards scalable engine concepts that could support the future deployment of low- and zero-emissions vessels worldwide.

COSCO Orders Milestone Dual-Fuel Order

[By: Everllence]

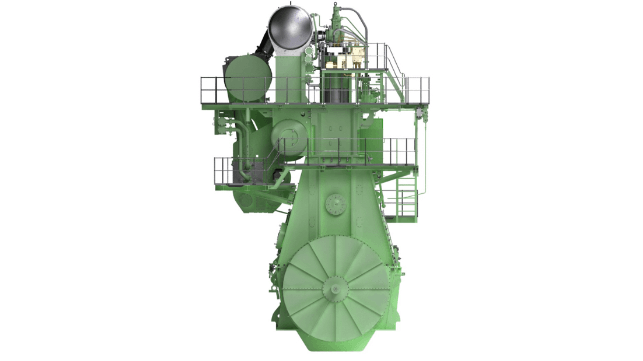

Everllence reports that it has received the 2,000th order for a dual-fuel engine from its two-stroke portfolio. COSCO Shipping Lines Co. Ltd. reached the milestone with an Everllence B&W 8G95ME—GI Mk. 10.5 main engine featuring EcoEGR (Exhaust Gas Recirculation) as part of an order for 12 such engines for a series of 12 x 18,000 teu container vessels currently under construction at Chinese yard Jiangnan Shipyard (Group) Co., Ltd.

Bjarne Foldager – Head of Two-Stroke Business, Everllence – said: “It’s very appropriate that this milestone was reached on the cusp of the Year of the Fire Horse – a particularly auspicious year in the Chinese calendar. China has been a very important market for us for over a century, just as COSCO is a valued customer.”

He continued: “Everllence’s dual-fuel strategy has led to multiple world-firsts in terms of oceangoing ships operating on a variety of alternative, low-emission fuels – confirming our leadership in this crucial marine segment. Our dual-fuel engines are showcases for environmentally friendly, reliable propulsion technology with seamless switching between fuels. On the path to net-zero, the marine industry needs willing partners and our thanks go to COSCO for its custom and friendship.”

Everllence states that, currently, just over half of its order book is dual-fuel measured in engine power. The 2,000-engine figure is a cumulative total for all engine orders from the company’s mature, efficient two-stroke portfolio that includes ME-GI (methane), ME-LGIM (methanol), ME-GIE (ethane), ME-LGIP (LPG), and the recently announced ME-LGIA (ammonia) engines.

Christian Ludwig – Head of Global Sales & Promotion, Two-Stroke Business, Everllence – said: “2025 saw a strong order intake for our two-stroke, dual-fuel engines, especially the ME-GI. Increasingly, decarbonisation and a general desire for fuel-flexibility as a strategic hedge are pushing their adoption. We have now gathered a decade’s worth of invaluable, dual-fuel service experience and operational data with which to further improve the technology. In the same vein, we are also delivering more digitally-connected engines that enable remote monitoring and provide impeccable data, allowing our shore-based engineers to make prompt recommendations on optimising engine performance in real time. We remain convinced that this strategy is the right one on the voyage to a low-emission fleet.”

The products and services herein described in this press release are not endorsed by The Maritime Executive.

No comments:

Post a Comment