Charting the Course for the Maritime Energy Transition in the Nordics

Leveraging the collaborative spirit for innovation

[By Mikael Lind, Wolfgang Lehmacher, Andreas Bach, and Nina Egeli]

The maritime industry is vital for global trade but significantly contributes to greenhouse gas (GHG) emissions. The Nordic countries, renowned for their innovative and sustainable practices, are taking decisive strides toward decarbonizing maritime transport. However, technological limitations, regulatory gaps, and infrastructure bottlenecks challenge the journey. This article explores the state-of-the-art maritime energy transition in the Nordics, the policies driving this change, and the resulting future opportunities.

The Case for Change

Shipping accounts for approximately 3% of global GHG emissions, projected to rise with economic growth. With their extensive maritime sectors, the Nordic nations are uniquely positioned to lead the energy and maritime transition through strategies such as:

- Fuel Switching: Transitioning to new energy carriers, e.g. methanol and biofuels

- Electrification: Fully or hybrid

- Wind assisted ship propulsion (WASP)

- On board carbon capture (OCC)

- Collaboration: Decarbonization will require coordinated efforts among governments, industry players, and research institutions to overcome barriers, such as resource scarcity, infrastructure gaps, and competition for low-carbon energy sources. A collaborative approach between the Nordic nations is essential for a sustainable future.

Policy Landscape

Nordic countries are setting ambitious GHG reduction targets for maritime transport, supported by a complex web of international, European Union (EU), and national policies:

International Regulations: The International Maritime Organization’s (IMO’s) GHG reduction strategy aims for net-zero emissions by 2050, but gaps in regulatory frameworks for emerging technologies like hydrogen and ammonia persist. The IMO has introduced measures like the Energy Efficiency Design Index (EEDI) and the Carbon Intensity Indicator (CII) to improve efficiency. The EEDI applies to newly constructed vessels, affecting a limited portion of global shipping tonnage. The CII was implemented to promote the reduction of CO2 emissions from ships in service.

EU Initiatives: The "Fit for 55" package integrates maritime transport into the Emissions Trading System (ETS) and mandates onshore power supply (OPS) for major ports by 2030. Complementary measures include the FuelEU Maritime initiative, which sets carbon intensity targets for ships, and the Alternative Fuels Infrastructure Directive, aiming to ensure infrastructure readiness for alternative fuels.

National Actions: Each Nordic country has tailored strategies. Norway’s Action Plan for Green Shipping emphasizes zero-emission ferries and hydrogen hubs, while Denmark’s "Towards Zero" strategy focuses on sustainable fuels like ammonia and methanol. Sweden and Finland invest in electrification and biofuels; Iceland is leveraging its renewable energy resources to drive maritime innovation.

Nordic initiatives: The Nordic governments have joined forces under a shared vision, stating that the Nordic region will become the world’s most integrated and sustainable region by 2030. Decarbonizing the maritime sector is an essential part of this vision, and Nordic collaboration and joint innovation are key enablers. Nordic Innovation, an organization under the Nordic Council of Ministers, has been running a Nordic Smart Mobility and Connectivity program since 2018, including a Green Shipping and a Sea Meets Land Mobility Mission for the maritime sector. In 2022, all Nordic Ministers for Environment and Climate approved a Declaration on zero-emission shipping routes between Nordic countries. Finland could become a neutral technology provider.

Innovation in the Nordics

The Nordics are at the forefront of maritime innovation, advancing electrification, alternative fuels, and other solutions like onboard carbon capture (OCC) and wind assisted ship propulsion (WASP).

Regarding electrification, Norway is leading with extensive onshore power supply (OPS) facilities and a growing fleet of hybrid and fully electric ships. Since 2020, Norway has funded 263 battery-powered aquaculture ships, 39 battery-powered fishing ships, and 12 battery-powered offshore ships. Today, 103 out of Norway’s 230 ferries are electrified. Medstraum, the world’s first fully electric fast ferry, indicates the potential for high-speed, zero-emission passenger transport.

Other Nordic nations are increasing their investments in battery-electric ferries and charging infrastructure. Denmark has innovated the delivery of electricity offshore, e.g., at green anchorage zones or wind farms.

Hydrogen is another area of focus, with Norway operating a hydrogen-powered ferry, Hydra, while supporting the development of hydrogen hubs for maritime use. The first pilot for a hydrogen value chain will be operational in 2025, featuring the first approved filling station for pressurized hydrogen and the first ocean-going hydrogen vessel. Aimed for operation between Oslo and Rotterdam, two container ships operating on liquid hydrogen are being developed. By also exploring zero-emission trucks on both ends, a green transport route will be established.

Ammonia-powered ships and associated fuel infrastructure are explored within the Norwegian Green Shipping Program, and the Ammonia Fuel Bunkering Network project. Like hydrogen, ammonia has a zero-carbon combustion profile, although life-cycle emissions associated with its production must be considered, and challenges to safety and regulatory standards remain. To accelerate regulatory development, a complete base document for draft Interim Guidelines on the safety of ships using ammonia as fuel was developed in the Nordic roadmap project and submitted to IMO. In 2022, Norway provided support for 5 hydrogen hubs and 16 ships. However, the allocated funding only led to investment decisions for one hub and two ships. The 2024 call for applications, in which funding was allocated to six ammonia-powered ships, offers an increased investment support rate. However, the industry continues to highlight significant challenges related to OPEX and high market uncertainty.

Sweden has pioneered the adoption of methanol, notably with Stena Germanica, which has driven new projects throughout the region. The use of methanol requires the retrofitting of engines and tank systems. Methanol for the propulsion of cargo ships has been assessed by prominent Danish engine designers and global container carriers, and major classification societies and the Danish Maritime Authority have given approvals. Internal combustion engines for the world fleet operating on methane, methanol, or ammonia have been developed in Finland and Denmark.

A concern with methanol and ammonia is their toxicity, which has profound health implications upon exposure. On the other hand, the maritime industry transports hazardous chemicals. Both ammonia and methanol can be considered common industry chemicals and, therefore, not extremely difficult to handle onboard. Instead, compared to traditional ones, the high costs associated with zero-emission fuel solutions are by many considered the main barrier to implementation, which is also valid for hydrogen and methanol.

Meanwhile, biofuels, including liquefied biogas (LBG), are increasingly blended with liquified natural gas (LNG) to lower emissions, offering a transitional solution as infrastructure for other alternatives develops.

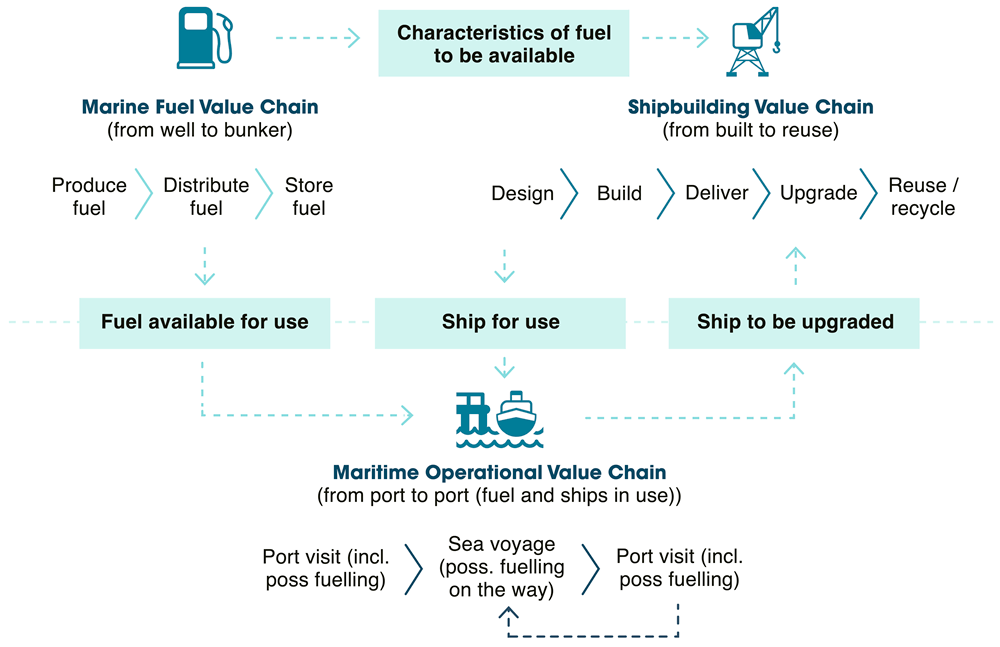

Three interrelated maritime value chains (Figure 1) are critical in decarbonizing shipping: marine fuel, shipbuilding, and maritime operational value chains. The marine fuel value chain provides sustainable fuel, the shipbuilding value chain produces ships and engines that run with green fuels, and the maritime operational value chain operates the ships with alternative fuels.

Figure 1: Three interdependent value chains and their dependency in the maritime sector

Production of sustainable fuels must be ramped up. While green methanol is hardly available, current green ammonia production would have to nearly double to switch 30% of shipping to this alternative fuel. In Finland, several projects are targeted to produce hydrogen to meet the increasing demand for ammonia.

Onboard carbon capture and storage (OCCS) can be applied as an alternative/complement to fuel switch. Sweden is emphasizing OCCS through the Stena Impero project which demonstrated the technical feasibility of OCCS systems, showing a reduction in CO2 emissions by up to 20% annually, with a manageable fuel consumption penalty of under 10%. OCCS systems require significant energy to operate. The initial capital expenditure (CAPEX) for installing OCCS systems is high, and operational expenditures (OPEX) increase due to higher fuel consumption and maintenance costs. Storing and offloading infrastructure remains to be built, and solutions such as ship-to-ship or ship-to-shore transfer of captured CO2 must be developed. Transportation and storage of captured CO2 is taking place in the Danish underground. Project Greensand has demonstrated that safe transportation of CO2 for injection into a depleted oil field is possible. The goal of Greensand is to store up to 400,000 tonnes of CO2 annually in the initial phase, with plans to increase capacity to up to 8 million tons annually by 2030.

Nordic countries are also making strides in wind assisted ship propulsion (WASP) technologies. Installing rotor sails on commercial vessels has demonstrated significant fuel savings and emission reductions, and amortization periods are reasonable. These innovative solutions harness wind energy to complement conventional propulsion systems, offering an immediate and scalable pathway to reducing maritime carbon footprints, with no unwanted consequences and infrastructure to be built. Some bridges and port equipment represent limited constraints. By leveraging advanced materials and aerodynamic designs, these systems align with the region's commitment to sustainable innovation and exemplify how traditional practices can be reimagined for modern sustainability goals.

The Green and Digital Corridor Initiative

Several Nordic-level maritime initiatives and innovation projects have been conducted over the years; some have been founded on well-established collaboration structures, while others have entailed the establishment of new cross-border ecosystems and networks. Building on insights from the Nordic Innovation-funded Maren project and its follow-up extension and the ambitions of the Clydebank declaration signed at COP26, Nordic countries are planning to establish a "Green and Digital e2e-Corridors in the Nordics" initiative as a transformative step towards sustainable transport. Anchored in the Umeå-Vasa maritime corridor and extending to the Umeå-Trondheim rail corridor, this initiative connects the Baltic Sea with the Atlantic Ocean via the Trondheim Fjord, exemplifying a multimodal green and digital corridor, reducing dependency on road freight while increasing the efficiency of transport.

This initiative's heart is the Umeå-Vasa maritime corridor, a critical route linking the Nordic region’s eastern and western transport systems. This corridor, complemented by the Umeå-Trondheim rail connections, exemplifies the integration of maritime and adjacent transport modes, forming a seamless end-to-end (e2e) logistics chain emphasizing sustainability, digitalization, and resilience. This corridor will significantly contribute to integrating the Nordic region and to seamless and connected cross-border mobility.

The corridor’s digital capabilities use the Virtual Watch Tower (VWT) initiative, enabling:

- Real-Time Emissions Tracking: Utilizing VWT technology for emissions calculations and transparency.

- Sustainability Leadership: Incorporating fossil-free fuels with clean ships while utilizing electricity-powered trains to minimize carbon footprints.

By integrating real-time emissions tracking, data-sharing technologies as the foundation for the use of advanced supply chain optimization tools, VWT fosters transparency, enhances disruption management, and is expected to support synchronized fuel provision as an additional use case to VWT. This community-driven approach enables stakeholders to co-create solutions and share primary data, optimizing logistics operations and reducing GHG emissions.

The corridor is also a sustainability leader, incorporating fossil-free fuels with one of the cleanest ships, Aurora Botnia. It also uses electricity-powered trains and onshore power supply systems to ensure the ship runs on electricity while docked and during operations in and out of the port.

The Umeå-Vasa-Trondheim corridor is a collaborative Living Lab for green and digital solutions that solve real-life problems. The initiative will be aligned with the efforts pursued in the Vinnova-funded “Green node in a Green Corridor”, capturing the ports’ emissions in Umeå and Vasa. Stakeholders such as shippers, transport operators, port authorities, fuel providers, and terminal operators work together to validate prototypes and refine technological solutions for scalability.

As a pilot project, the corridor expanded beyond the maritime corridor, will demonstrate how integrated green and digital corridors can operate at scale. The insights will inform similar initiatives across the Nordic region and beyond, positioning the Nordics as a global leader in sustainable logistics.

Market Formation Challenges and Policy Recommendations

Despite continuous progress, the market for alternative fuels is still in its infancy. High initial investments and limited production capacity hinder adoption, as many alternative fuels remain considerably more expensive than conventional marine fuels. Regulatory uncertainty further slows development, particularly around standards for emerging fuels like hydrogen and ammonia. Harmonizing regulations across countries and ensuring compatibility with international standards are critical to overcoming these barriers. Additionally, infrastructure gaps pose a significant challenge. Ports require substantial upgrades to support bunkering and OPS for alternative fuels. Developing hydrogen and ammonia bunkering facilities necessitates coordinated planning and significant capital investment. The participating stakeholders must be digitally integrated to coordinate and optimize their activities.

The MAREN project addresses these challenges by emphasizing several policy priorities.

- Strengthen Market Incentives: Enforce GHG taxation, promote green public procurement, and implement stricter environmental requirements for offshore operations that encompass the entire lifecycle and fishing licenses.

- Level the Playing Field for Alternative Fuels: Introduce the polluter-pays principle.

- Build Regulatory Capacity: Develop standards for alternative fuels and build emerging technology expertise to address cross-sectoral value chain bottlenecks

- Mobilize Resources: Fund research and development (R&D) and support port infrastructure upgrades.

- De-Risk Investments: Use contracts for difference (CfD)[1] to accelerate innovation.

- Adopting a holistic value chain approach: Consider the interrelated value chains (Figure 1) to ensure the alignment of renewable energy production with maritime decarbonization goals. and consider the entire lifecycle of alternative fuels, from production to end use, to create a comprehensive framework for sustainable maritime energy transition.

Conclusion – The Corridor Ahead

The maritime energy transition in the Nordics reflects the region’s commitment to sustainability and innovation. Innovation is more than just creating new technologies—it involves building markets, mobilizing resources, and gaining societal acceptance, all crucial for the success of sustainable solutions in maritime transport.

Collaborative initiatives like the "Green and Digital e2e-Corridors in the Nordics" provide a roadmap for scaling green and digital technologies. By addressing regulatory gaps, fostering innovation, and investing in infrastructure, the Nordics can set a global benchmark for sustainable shipping. The collaborative model rooted in the Nordics can be seen as a role model for the world in terms of how actors could come together to tackle grand challenges.

Decarbonizing maritime end-to-end supply chains is a global imperative. The Nordics' proactive approach—supported by ambitious policies and collaborative frameworks—demonstrates that sustainable maritime transport is achievable. As these nations continue to innovate, their experiences will serve as a blueprint for global efforts toward a zero-emission maritime industry.

Acknowledgment

We are grateful for the comments provided by Valdemar Ehlers (Danish Maritime), Cecilia Gabrielii (SINTEF Energy), Ida Kallmyr Lerheim (RENERGY), Teemu Manderbacka (VTT), Lasse Pohjala (VASEK), and Jon Björn Skulason (Icelandic New Energy Ltd), in the development of this article.

About the authors

Mikael Lind is the world’s first (adjunct) Professor of Maritime Informatics engaged at Chalmers, and Research Institutes of Sweden (RISE). He is a well-known expert frequently published in international trade press, is co-editor of the first two books on Maritime Informatics, and is co-editor of the book Maritime Decarbonization.

Wolfgang Lehmacher is a global supply chain expert, partner at Anchor Group, and advisor at Topan AG. The former director at the World Economic Forum, and CEO Emeritus of GeoPost Intercontinental, is an advisory board member of The Logistics and Supply Chain Management Society, ambassador F&L, and advisor Global:SF and RISE. He contributes to the knowledge base of Maritime Informatics and co-editor of the book Maritime Decarbonization.

Andreas Bach is Director of Maritime Systems Innovation at RISE, Research Institutes of Sweden and Manager of Swedish Maritime Technology Forum, SMTF. Andreas has long experience in the maritime domain focusing on leadership, the transition towards a sustainable industry and maritime innovation systems.

Nina Egeli is head of Nordic Smart mobility and Connectivity at Nordic Innovation. Nordic Innovation aims to make the Nordics (Denmark, Finland, Iceland, Norway and Sweden) a pioneering region for sustainable growth and works to promote entrepreneurship, innovation and competitiveness in Nordic business. Nordic Innovation is an organisation under the Nordic Council of Ministers.

[1] A Contract for Difference is a private law contract between a low-carbon fuel producer and a government entity, designed to stabilize prices and encourage investment in renewable energy technologies.

The opinions expressed herein are the author's and not necessarily those of The Maritime Executive.