Ship Operators to Join Trial To Prevent Two-Stroke Engine Scuffing

CM Technologies (CMT), a leader in advanced condition monitoring solutions, is calling on shipowners and managers to join collaborative trials designed to capture vital data on one of the shipping industry's most costly problems: cylinder liner scuffing in two-stroke engines.

Scuffing, a form of sudden severe wear, can result in catastrophic engine damage and vessel downtime. And while it’s a well-known issue, typically affecting large two-stroke diesel engines found on bulkers, tankers, and large container ships, the root causes are difficult to pin down. Operators, OEMs, and service providers have long struggled to predict or prevent the phenomena.

Germany-based CMT, however, has developed a system that can alert operators to early onset cylinder damage, but see seeks trial partners for critical data gathering aimed at validating the sensor’s predictive capabilities and to prevent engine damage before it occurs.

“Scuffing is a silent killer. It can occur suddenly, and the damage can be extensive,” said Uwe Krüger, Managing Director at CM Technologies. “Despite the prevalence of this issue, even engine manufacturers don’t fully understand why it happens. What we do know is that it’s linked to a combination of factors, like lubrication failure, drastic load changes, recent overhauls, amongst other things. Our goal is to better understand the acoustic fingerprint of scuffing so we can prevent failures before they happen.”

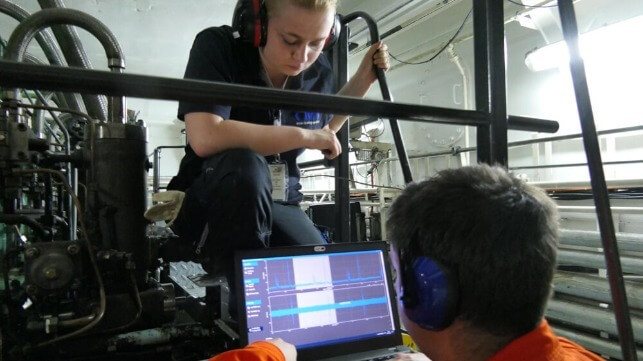

CMT’s recently developed Scuffing Sensor system – a “stethoscope for cylinder liners” – uses high-frequency acoustic emission (AE) technology to detect the earliest signs of friction and wear from outside the cylinder.

Unlike other methods that rely on visual inspection or oil analysis performed weeks apart, this approach captures real-time acoustic data without interrupting engine operation. By identifying wear-related noise patterns, the system provides a potential early-warning signal before damage occurs.

Trial partners are invited to deploy the system onboard vessels equipped with two-stroke diesel engines. Ideally, these vessels will call at ports in Northern Europe, Germany, the Netherlands, Belgium or France, where CMT engineers can easily access them to install and retrieve data-logging equipment.

The system itself is unobtrusive, requires no modifications to engine internals, and is non-invasive. Mounted externally using magnetic brackets, the sensors require no disassembly, no drydock visit and no interruption to the ship’s voyage.

“There’s no need to open the engine or stop operations. The sensor system is magnetic, sits externally on the cylinder, and records data quietly in the background,” said Krüger “We’re looking for operators that will let us place this technology onboard for one to three months. The process is simple, and the benefits could be significant.”

By participating in the trials, ship operators and managers stand to gain early insight into the scuffing risks on their engines, while helping CMT further develop the breakthrough diagnostic tool for the wider industry.

“If we can collect enough data from a range of engines, we can build a reliable library of friction noise patterns,” Krüger said. “This will enable us to deliver early warnings when problems are brewing, long before current monitoring methods can detect them. The benefits will be lower maintenance costs, less downtime, and better protection of what is undoubtedly the most critical, high value asset onboard a ship, aside from the crew.”

CMT believes this collaborative approach is key to cracking one of shipping’s most persistent maintenance problems.

“We’re not asking shipowners to shoulder any risk, just to let us listen to their engines. Together, we can create something that protects engines, saves money, and sets a new benchmark for condition-based maintenance.”

Shipowners or managers interested in participating in the scuffing detection trials are invited to contact CM Technologies at info@CMTechnologies.de

The products and services herein described in this press release are not endorsed by The Maritime Executive.

Industry Leaders Take Action to Revolutionize the ARA Bunkering Market

In a groundbreaking development for the global marine fuels industry, leading shipping and bunkering companies have come together to launch a Bunkering Services Initiative focused on solving the widely reported issues of fuel quantity shortages and fuel quality opacity across the marine fuel supply chain. By addressing these market distortions marine fuel buyers can make optimal procurement decisions and suppliers can operate on a level playing field.

Open Participation

The Initiative is voluntary, and participation is welcome from all marine fuel buyers and suppliers who commit to adopting and complying with its standards and governance.

Scale from Day One

At the outset focused on Amsterdam-Rotterdam-Antwerp (ARA), the world's second-largest bunkering hub, the Initiative represents 20% of ARA market volume comprising several thousand deliveries each year. Founding participants include some of the most prominent names in the industry, including Cargill, Frontline, Hafnia, Hapag-Lloyd, Mercuria, Minerva Bunkering, Oldendorff, Trafigura, TFG Marine, Unifeeder, and Vitol, as well as other key players in energy and shipping.

Self-Regulation

The concept is uniquely designed to be self-regulating, leveraging powerful data-driven insights to monitor participant behaviour and adherence to standards – thereby advancing the objectives of regulatory authorities without requiring their administration.

Gold Standard

The Initiative defines a new gold standard of technology-enabled bunkering operations, with seamelss integration of mass flow meters, digitalized workflows over the blockchain, traceable fuel quality measurements throughout the supply chain, full accounting of quantity balances, and real-time reporting to participants.

Commitment to Accountability

To ensure accountability to the Initiative's objectives and standards of operation:

- Lloyd's Register has been appointed as the System Auditor, responsible for qualifying participating bunker barges, conducting unannounced physical barge inspections, and verifying compliance with Initiative standards and data integrity (lr.org).

- ADP Clear Pte Ltd has been appointed as the Initiative's technology provider, facilitating multi-party workflows, real-time reporting, and verifiable performance metrics for all stakeholders (adpclear.io).

Join Us

Any marine fuel buyers and suppliers engaged in the ARA market and interested in participating in the Initiative can direct their inquiries to initiative@adpclear.io.

The products and services herein described in this press release are not endorsed by The Maritime Executive.

Corsica Linea Ferry Gains Fuel Savings with Wärtsilä Retrofit Package

[By: Wärtsilä]

Technology group Wärtsilä’s retrofit package for the Corsica Linea ferry ‘Pascal Paoli’ has resulted in fuel savings of up to 22 percent. This significant gain in energy efficiency on each trip has been made possible by the installation of a new twin screw controllable pitch propeller (CPP) system with blades optimised for the ship’s operating profile, the Wärtsilä EnergoProFin energy saving propeller cap, a controls retrofit, and combinator curves for the ship’s various operating modes.

These upgrades, which were completed at the end of 2024, were validated through CFD (computational fluid dynamics) open water simulations, and confirmed during sea trials with the chief engineer. In monetary terms, the fuel savings equate to an estimated 7,700 US Dollars per trip. The related reduction in emissions represents a massive step in Corsica Linea’s decarbonisation journey, allowing the company to remain compliant with the stricter requirements on carbon emissions.

“We are extremely happy with the efficiency improvements resulting from this Wärtsilä retrofit package,” says Xavier Esnault, Energy transition project manager at Corsica Linea. “The fuel savings are important, both from a cost perspective, as well as supporting our decarbonisation strategy to reach a reduction of 40% of our CO2 emissions by 2030.”

The ‘Pascal Paoli’ is a 174-metre long RoPax ferry operating between Marseille and Bastia. Ferries are on the front line of the energy transition and are among the first sectors to target net zero-carbon operations. At the same time, operators are expected to provide a reliable, efficient on-time service, while keeping operating costs under strict control.

“Ferry operators, such as Corsica Linea, are looking to leverage technologies that offer minimal service disruption and a maximised return on investment, all while reducing their carbon footprint. For this reason, the fuel efficiency upgrade carried out on the ‘Pascal Paoli’ was done with the aim of supporting Corsica Linea with achieving these goals,” comments Andrey Dudko, Product Manager, Propulsion – Wärtsilä Marine.

The ’Pascal Paoli’ operates with two Wärtsilä 46 engines per shaftline. It has a number of operating modes, including sailing and manoeuvring with one or two engines per shaft line. The changes resulting from the retrofit project did not impact the vessel’s manoeuvrability.

This upgrade comes at a time when ferry operators are under increasing pressure to decarbonise. The IMO’s new Net-Zero Framework through the GHG fuel intensity (GFI) provides a clear incentive for operators to invest in energy-efficiency solutions, such as the technologies leveraged for this retrofit project. By placing an explicit price on GHG emissions, the IMO has sent a strong market signal that energy efficiency technologies and alternative fuel solutions must be part of every shipowner’s toolkit. This framework encourages industry stakeholders to invest in immediate operational improvements, explore onboard abatement solutions, and accelerate the roll-out of sustainable fuels.

The products and services herein described in this press release are not endorsed by The Maritime Executive.

No comments:

Post a Comment