An analysis of the Val d’Agri oil field in Italy provides insight into how processes associated with wastewater disposal trigger earthquakes — and how such effects can be reduced to maintain the economic viability of mature oil fields.

Mirko van der Baan

Gas and oil extraction generates wealth — it can significantly boost the gross domestic product of a country. But water is also extracted with the hydrocarbons, and is often reinjected into the ground for disposal. Unfortunately, large-scale fluid injection can induce earthquakes1, potentially leading to the termination of extraction before the full economic potential of an oil field has been realized. Writing in Nature, Hager et al.2 describe a multidisciplinary process to manage earthquake hazard in an active oil field, maintaining the economic viability of a field that uses fluid injection for water disposal, while minimizing the likelihood of seismic activity that is sufficiently strong to be felt by humans.

Worldwide hydrocarbon extraction of both natural gas and petroleum liquids has increased steadily (see go.nature.com/3hnqdat) since the mid-1980s (although the COVID-19 pandemic has interrupted this long-term trend). The water produced during the process must be treated, recycled or disposed of, because it is salty and contaminated by hydrocarbons and other organic and inorganic compounds3. Moreover, wastewater production tends to increase with the maturity of an oil field. This effect, combined with the sustained increase in hydrocarbon extraction, means that the disposal of wastewater is a growing global challenge.

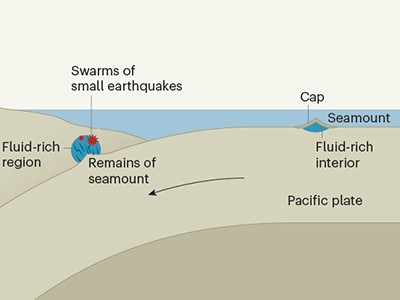

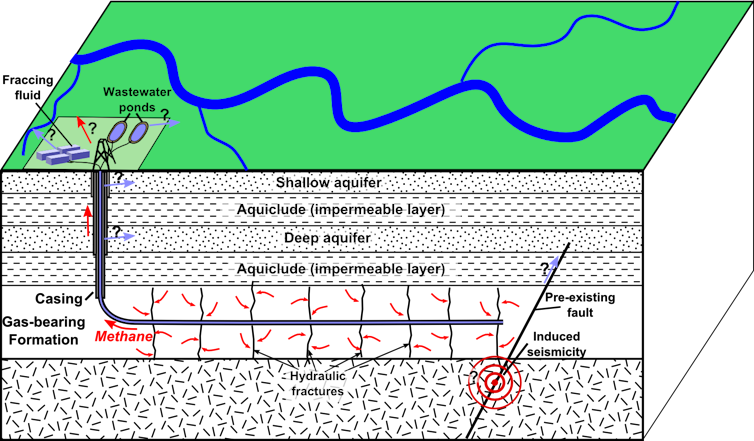

Although most earthquakes are caused by tectonic forces, they can also be triggered by fluid injection into bedrock, most commonly when fluids penetrate pre-existing faults. The associated increase in fluid pressures reduces frictional resistance to slip, which, in turn, can reactivate the fault and trigger an earthquake (Fig. 1). Fluid injection and hydrocarbon extraction can also cause large changes in volume or mass underground that exert stresses on nearby, pre-existing faults, resulting in seismic activity1,4. In the past few years, various regions have undergone significant changes in earthquake-recurrence patterns owing to large-scale fluid injection — including Oklahoma in the United States5, the Sichuan Basin in China6 and the Western Canadian Sedimentary Basin7. Such changes have been observed for fluid injection associated both with water disposal1,5 and with hydraulic fracturing (fracking)8.

Fluid-flow simulations are typically used to investigate correlations between earthquake patterns and fluid injection9. This approach provides insight into the underlying drivers of earthquake occurrence in tectonically quiet areas. However, fluid simulations alone are probably insufficient for developing strategies to manage seismicity, particularly in areas in which tectonic earthquakes are common, because the dominant cause in such regions is explicitly ignored.

Hager et al. have developed a multidisciplinary approach to earthquake mitigation in Italy’s Val d’Agri field, which is located in a tectonically active area. Val d’Agri is the largest onshore oil field in Western Europe. Extraction started in 1993, and the field now accounts for more than half of Italy’s oil production. Wastewater disposal started in 2006 and led to about 300 small seismic events (maximum local magnitude 2.2, which is too small to be felt). Historically, an average of about four tectonic earthquakes of moment magnitude equal to or greater than 5.5 (strong enough to shake and possibly damage buildings) occur each century within 100 kilometres of the fluid-injection site. So, what injection rate is safe — that is, unlikely to trigger substantial seismic activity?

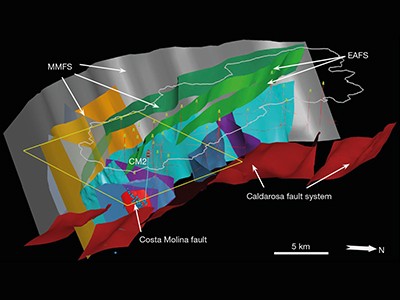

The authors developed a multi-step, process-based approach to address this question. First, they produced a 3D structural model of the Val d’Agri region, 80 × 50 × 10 km in size, containing 22 known major faults, surface topography, the top of the hydrocarbon reservoir and the rock that seals it off. The model contains the entire Val d’Agri oil field and includes 24 active hydrocarbon-producing wells. Fluid flow is coupled with geomechanical processes in the model to replicate the effects of external tectonic forces, hydrocarbon extraction and fluid injection from 1993 to 2016. The model parameters were estimated and calibrated using many data sources, including GPS data, records of well pressures and reflection seismology (which uses reflected seismic waves to determine the structure of Earth’s subsurface).

Next, the authors constructed a smaller 3D model, 13 × 13 × 15 km in size, incorporating 17 faults and the producing wells in that region. This model focuses on the oil field’s fluid-injection well and the associated earthquake locations. Coupled modelling of fluid flow and geomechanical processes was again carried out using the larger model to constrain the behaviour of the smaller model at its boundaries. The smaller model was then used to evaluate local stress and slip conditions at faults over time.

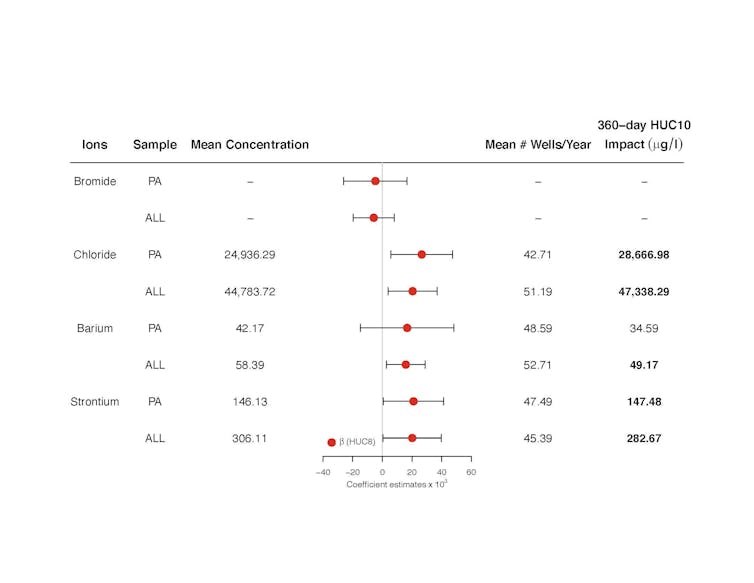

The simulations show that stresses have stabilized in most of the area around the injector well, because hydrocarbon extraction has reduced fluid pressures and therefore increased resistance to slip on most faults. Conversely, fluids have penetrated a fault near the injector well, causing the observed small-magnitude seismicity in that area. The authors then combined the output of the smaller model with earthquake-physics models. They found that the results matched available observations of fluid flow within the hydrocarbon reservoir and observed seismicity patterns — including the dependence on past injection rates of the location, timing and evolution of the earthquakes. The calibrated model suggests that a rate of fluid injection of 2,000 cubic metres per day, which corresponds to 50% of current total wastewater production, is unlikely to trigger noticeable seismicity above the tectonic background rate, whereas small events are increasingly likely to be triggered at higher rates of 2,500 and 3,000 cubic metres per day.

Hager and colleagues’ work is unusual for several reasons. Their method relies on the availability of detailed data and expert knowledge of many aspects of the region and its wells. Unfortunately, it is unusual to have such detailed information. The authors’ results are the product of a highly fruitful partnership between academia and industry. As such, the findings provide insights that might result in the development of new industrial practices for managing and mitigating seismicity triggered by hydrocarbon extraction.

For instance, an ongoing case of triggered seismicity is the Groningen field in the Netherlands, the largest gas field in Europe. A gradual rise in seismicity since 1991 in this region caused property damage and led to increasingly vocal public discontent, resulting in the decision to terminate extraction in 2022. This will leave around 20% of potentially recoverable gas, worth about €70 billion (US$83 billion), in the ground (see go.nature.com/3blwz2c). Application of Hager and co-workers’ method to this region might enable the remaining gas to be extracted without causing further damage.

If the authors’ approach can be extended to seismicity associated with hydrocarbon extraction, as well as that associated with wastewater injection, it might help to manage and mitigate the associated environmental impacts if used at the nascent stage of seismicity. Their method might also be suitable for managing earthquakes associated with the sequestration of carbon dioxide10 and engineered geothermal systems11,12.

Phenomena associated with hydrocarbon extraction are often contentious13, but Hager et al. have developed a process for managing and mitigating one of the most important adverse effects: induced seismicity. It is to be hoped that this will help the oil and gas industry to manage the balance between the economic viability and the environmental effects of extraction.

Nature 595, 655-656 (2021)