23 Ports Want Congress to Restore HMTF Funding for Berth Improvements

America's biggest port authorities are calling for Congress to restore funding allocations from the Harbor Maintenance Trust Fund (HMTF), a frequent battle in the appropriations process. If maintenance funding is not restored to levels approved in a bipartisan agreement back in 2020, the U.S. port system will lose $1 billion in federal investment over the course of the rest of President Donald Trump's current term, according to the American Association of Port Authorities (AAPA).

The HMTF is funded by a small 0.125% value-added tax on goods entering U.S. ports. The HMTF's proceeds pay for maintenance dredging, jetties, breakwaters and related projects, all for the purpose of keeping federally-supported harbor navigation open. About half of all HMTF tax proceeds come from big "donor" ports and energy ports, which generate millions per year each in fees - but historically, these ports have received only about two percent of the appropriations back from the fund.

In 2020, Congress agreed to allocate funds on a percentage basis among different types of ports, sharing the resources more equitably. Emerging harbors would get 20 percent, Great Lakes Ports would get 12 percent, and donor ports would get 10 percent for "expanded uses" like berth dredging, in-water repairs for wharfs, or projects to ensure slope stability at a berth. So far, that formula has only been applied in practice once, according to AAPA: it was used in FY2024 for a $330 million allocation for donor ports. However, the funds were omitted in the FY2025 USACE Work Plan, and the administration left them zeroed out again in its FY2026 budget request Work Plan as well.

"Donor and energy transfer ports, which were expecting to receive nearly $330 million in Section 102 funding to continue the important work started with FY24 funding, ultimately received no funding for this program in the Work Plan," 23 signatory ports said in an open letter to key House and Senate subcomittee leaders. "Similarly, the FY26 budget request includes no funding to carry out Section 102."

The Trump administration's budget request for USACE civil works for FY2026 is $2 billion less than the enacted budget in the last two fiscal years. The administration's total request for HMTF funding comes to $1.7 billion, $1 billion less than last year's enacted budget. In an explanatory statement, the administration noted that $1.4 billion from the FY2024 HMTF appropriation remained unobligated in early 2025; since there are unspent funds still on the table, "there is no need to request more funding than necessary, which is why the Budget reduces funding for HMTF" for FY2026, the Office of Management and Budget (OMB) said in a statement.

"In this [White House budget] request, spending on projects that are not a Federal responsibility (e.g., dredging of berths) is limited, whereas projects like maintaining commercial navigation on Federal channels are prioritized," OMB said.

California Extends Carbon Capture Barge Service to Tankers

The California Air Resources Board (CARB) issued an executive order that authorizes the expanded use of the carbon capture barge service of STAX Engineering to service tankers. The order is timely as CARB’s Ocean-Going Vessels at Berth regulation took effect for tankers at the Ports of Los Angeles and Long Beach as of January 1 and extends to all California ports as of 2027.

Crude oil, product, and gas tankers make up a significant part of California’s maritime trade, but due to safety concerns, they are unable to use shore power. California, however, is extending its requirements to tankers as well as containerships, car carriers, and other large vessels to reduce their emissions while at dock. It would require a costly retrofit to older ships to use shore power, or they had to find other means to meet the new emissions regulations.

“Tankers are the backbone of global energy infrastructure—with over 1.3 million barrels of crude oil alone arriving just in California ports daily—yet they’ve lacked a safe, practical solution for meeting rising emissions standards,” notes Mike Walker, CEO of STAX Engineering. “Our technology fills that gap. It helps operators comply with regulations while improving air quality for surrounding communities.”

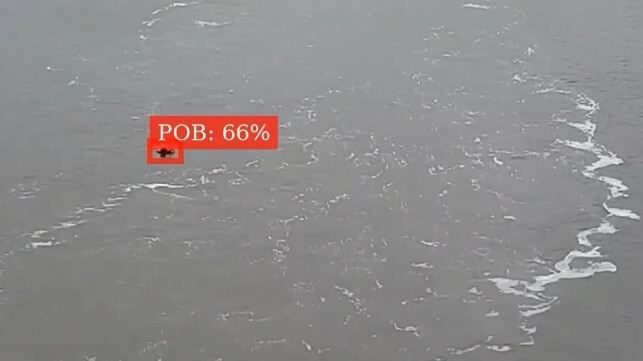

STAX uses a mobile, barge-based emissions capture and control system. It connects directly to the vessel’s smoke stack or exhaust system without any modification and with no requirements for power. The system captures exhaust from auxiliary engines and removes up to 99 percent of particulate matter and 95 percent of nitrogen oxides (NOx) emissions.

The company has already been making its services available at California’s five main ports, and since early 2024, reports it has treated 1,192 vessels for a cumulative 25,000 hours. It reports this has captured 190 tons of pollutants, with nearly 1,000 hours already dedicated to tankers.

Under the inaugural executive order, STAX received approval for four barges. The company points out that it already has contracts with the tanker berth F209 at Olympus Terminal in Los Beach, as well as Shell’s Mormon Island Terminal in the Port of Los Angeles, and will be working with MIL Chemical among others.

Currently, its services are dedicated to California. The company reports that by 2027, it will have a fleet of 27 operational barges and presence in all California ports when tanker emissions regulations expand to Northern California. The company also recently secured £1.1 million in UK government funding through the Clean Maritime Demonstration Competition for the PortZero project, a collaboration with Seabound, Associated British Ports, and Lomar Shipping, for its international expansion project.

New Zealand Wants to Reverse Declining Port Productivity

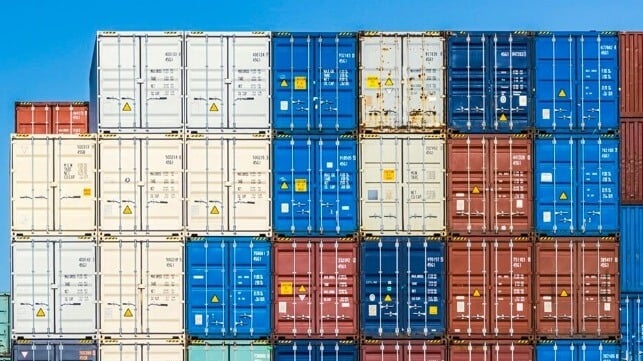

Amid concerns of declining ports productivity in New Zealand, the country’s parliament is progressing with an inquiry aimed at revamping the maritime sector. According to data by the Ministry of Transport, most of New Zealand ports are struggling to reach pre-pandemic growth levels. In the past decade, total container loads and unloads across the six New Zealand container ports increased annually by between 3-8 percent. The peak growth period was in 2016-2017 before dropping at the onset of Covid-19 pandemic.

In its submission to the parliament inquiry, the Maritime Union of New Zealand (MUNZ) decried lack of a national ports strategy, which has led to disorganized competition amongst terminals. Currently, New Zealand has around 13 ports open to international cargo vessels. Most of these ports are in proximity of each other, causing inefficient competition. In addition, there have been attempts by some smaller ports to over-invest in infrastructure for large international vessels, which they rarely attract.

To address these issues, MUNZ has recommended for a unified New Zealand Ports Strategy centered on a hub and spoke model. “This model would designate 2-4 main import/export ports (hubs) with regional ports (spokes) feeding goods to and from these hubs via reliable coastal shipping,” added MUNZ.

The International Container Lines Committee (ICLC) representing international container shipping lines in New Zealand, also made a submission, calling for lifting of productivity across all ports in the country. “We note that overall, the ship rate has reduced from 68 moves per hour in the first quarter of 2019 to 55 moves per hour during a similar period in 2025 across the four largest ports. This is close to a 20% reduction in productivity and is very concerning,” said ICLC. Ship rate is a port productivity indicator tracking the number of containers moved on and off a containership per hour.

Some ports appear keen to resolve these challenges. Last week, Ports of Auckland got provisional approval via the newly enacted Fast Track law, which will see the facility invest $118 million in a berth expansion project. This will include expanding the northern berth at the Fergusson container terminal by 45 meters. In addition, a new 330m wharf will be built at the northern end of the Bledisloe terminal. These developments are partly aimed at enabling Port of Auckland to handle larger vessels as freight needs continue to evolve, according to the port’s CEO Roger Gray. Overall, the port is planning to spend around $240 million in capital projects by 2030.

Top image: Simon Oosterman / CC BY NC SA 2.0

Azerbaijan: SOCAR Container Terminal in Turkey Not for Sale

The Azerbaijani state-owned energy company SOCAR has denied claims that it is looking at options for selling its container port in Turkey. The facility, SOCAR Terminal, is the biggest port in Turkey’s Aegean region, with a container handling capacity of 1.5 million TEU. The construction of the port was completed in 2018.

However, Bloomberg last month reported that SOCAR Türkiye Energy was holding talks with buyers for potential sale of SOCAR Terminal. The deal was reportedly meant to raise capital for the operator’s parent company, SOCAR Group, as it prepares to invest $7 billion in the expansion of its petrochemicals portfolio in Turkey.

But in an interview with the Turkish newspaper Dunya, SOCAR Terminal CEO Uygun Degirmenci said that the port is not on sale. Instead, an additional investment is underway to upgrade the terminal. SOCAR has so far invested $420 million in the terminal.

“Terminating our operations in the terminal is definitely not on SOCAR’s agenda. On the contrary, last week the company’s board of directors made decisions that will take us to a new level through the introduction of new equipment and additional investment in digitization, ensuring an increase in capacity,” commented Degirmenci. He also revealed that SOCAR Terminal is exploring cooperation opportunities with strategic partners to expand its terminal operations. This is part of a wider effort by SOCAR Terminal to boost its port operations.

Last month, SOCAR Terminal acquired the remaining 93% stake in port operator Petlim from the Turkish petrochemical company Petkim. Petlim was established in 2010 to help in developing Petkim port into the current SOCAR Terminal. Petkim port was initially built in 1985 to serve as a petroleum export facility.

Last year, SOCAR Terminal served 630 vessels and handled 541,000 TEUs.

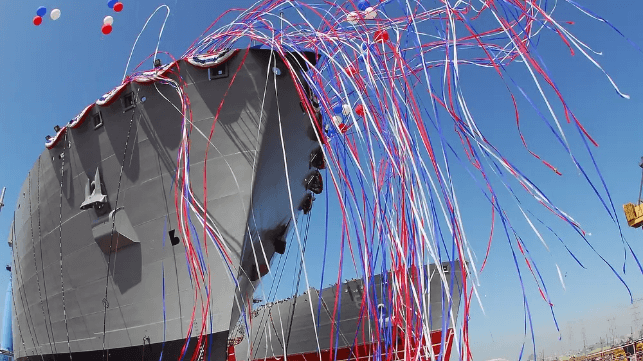

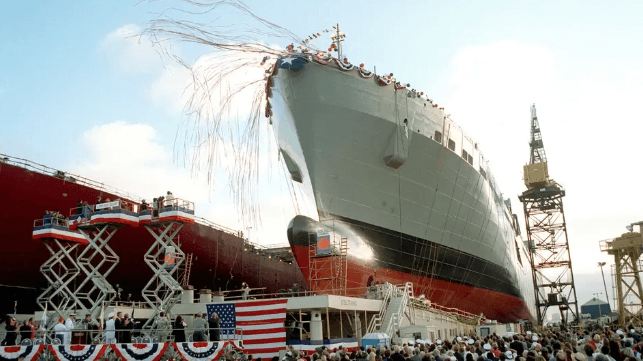

SHIPS for America

SHIPS for America

The

The